Shipping Containers Heat Protection

Super Therm® insulates from the initial HEAT LOAD which is the beginning of the heat transfer measurement. It is a fact, that if you “reduce the amount of heat in the initial loading, you have reduced the amount of heat “available” for transfer into the shipping container”.

Get the Longest Lasting Coating for Shipping Containers

Are you looking for the best coating for shipping containers? By using the right coatings you can prevent rust and corrosion and extend the life of your shipping containers, container home, ISBU (Intermodal Steel Building Unit), or workspace, while getting a great finished look that will last for over 20 years. Our corrosion coating Rust Grip can actually bond to, and strengthen, rusted or corroded metal surfaces. You can even use our coatings to patch up rusted holes.

Concerned about heat when your container is in direct sun? Super Therm® and Sunshield insulate solar heat to keep the surfaces cool while taking up no space. Ideal for shipping container homes, converted workspaces, or storage units. Our architectural grade top coat Enamo Grip can be custom tinted and have unsurpassed semi-gloss/colour retention. They also have exceptional scuff/impact resistance.

Use of Super Therm® for Shipping Containers Insulation around the world

- Super Therm® covers Brooklyn, NY Shipping Container

- Mobile Phone Containers Vodafone Turkey

- Houston, Texas, Super Therm® on Shipping Container Home

- Origin Energy Shipping Containers

- Tampa Bay – Building with Steel Shipping Containers and Super Therm®

- Hepburn Springs, Victoria Container Home “fantastic environmentally“

- DryDocks World (Dubai) Super Therm Container Test Results

- Italian desert summer Container Residence

- Redondo Beach Shipping Container House

- El Salvador Super Therm® ‘Magic Paint’

Shipping Container application tips

- Super Therm® Coverage for a shipping container

- Recommended coating system for shipping containers

- Container Condensation Control

Shipping containers are rapidly becoming an alternative living option. Super Therm® as the base is the perfect option to affordable heat protection options. Condensation control.

Super Therm® ceramic solar heat insulation on shipping containers offer:

- Near total solar heat insulation

- 367 to 4 infrared BTU insulation

- Energy reduction

- Reduce expenses

- No priming

- Outstanding heat insulation coating

- Mould/mildew resistance

- Class ‘A’ fire protection (no spread)

- Water resistance

- 50-68% sound reduction

- No additional building required

- Convenient

- Personal comfort

Shipping Container benefits with Super Therm®

Super Therm® weather resistive barrier, solves many of the challenges facing traditional house wrap and building paper. A fully-adhered system is the best insurance against water and air intrusion. Super Therm® is a fluid-applied, seamless protection for moisture sensitive structures in the event of a breach in exterior wall coverings. Super Therm® protects against ingress of incidental water such as that caused by severe weather, vapour or condensation (shipping container condensation), into the building or facility.

Class A fire resistance for all walls or roofing it covers. ASTM E-84 is “0” flame spread and “0” smoke.

Sound reduction through walls or roofing where Super Therm® is applied. ASTM E90 “Standard Method for Laboratory measurement of Airborne Sound Transmission Loss of building Partitions”, and ASTM E413 “Standard Classification for Determination of sound Transmission Class”. Sound Transmission Coefficient up to 50%.

Water Barrier protection to a 88km/ph (55mph) wind driven rain. ASTM D 6904

Resistance to Wind Driven Rain for Exterior Coatings. ASTM D7088, Resistance to hydrostatic Pressure for Coatings.

Mould/Mildew Resistance. ASTM D3273-82T tested for severe mould environment – temperature 90°F (32°C) and RH of 95%-98% for 5 1/2 weeks. Rated 9 out of 10.

Solar heat load insulation. In the field of heat protection, the standard “R” (resistance) value is a measurement of how fast the heat will conduct or travel through traditional materials. Super Therm® multi-ceramic solar heat insulation coating reduces the total solar heat load and is tested from 367 to 4 BTU of infrared heat therefore does not utilise the R value as there is no resistance, just physics and science.

Super Therm® covers Brooklyn, NY Shipping Containers

A couple in Brooklyn build their dream home from shipping containers. Shipping containers are commonly seen carry goods all over the world, but one couple in New York calls them ‘home.’ Michele Bertomen and David Boyle have built their home after purchasing a small plot of land in the trendy Brooklyn neighbourhood of Williamsburg.

Super Therm® ceramic heat insulation coating was used on the interior of the home, and concrete radiant floors help to heat. Read the Article >

Vodafone Mobile Phone Containers, Turkey

For transmitting the reception signal for mobile phones in Turkey, an air-conditioned container with electronic equipment is used. The problem is that the containers can overheat with extreme outside temperatures (30°C+) with the result that the equipment will malfunction or even break down.

One of the parameters is that the container had to have a constant inside temperature of 24°C that could often not be reached with the air conditioner that was used.

The problem is that there are significant electricity costs for cooling the container to the right, constant temperature of 23°C. The containers are 2 x 2 x 3 meters, which are 24m2 for the entire container, bottom excluded.

Treat the container with Super Therm® on the outside to reflect the direct sunlight, so that the air-conditioner can reach the inside temperature of 23°C more easily and that eventually energy reduction will occur.

Conclusions: Inside temperature of 23°C was reached. An average energy reduction was achieved. See the report >

I

Super Therm® on Shipping Container Home in Houston, Texas

Insulation and structure for both the roof and flooring comes from SIPs (structural insulated panels). Meanwhile the exterior and undersides of all the containers is coated in a thin ceramic coating called Super Therm® – which is amazingly non-toxic, has received Cradle to Cradle certification!

Besides the amazing heat insulation properties of the home, there is natural daylight streaming in from clerestory windows and a large glass facade on the east of the house. Interior materials were recycled and/or non-toxic, paints and finishes are low-VOC, efficient HVAC systems, super tight construction with energy recovery ventilation, porous paving and much more. Additionally, during construction, waste was kept to a minimum and recycled whenever possible, so at the end construction, there were only 12 contractor bags of trash. Read more >

Origin Energy Shipping Containers

“We use a shipping container to store our CO2 cylinders. The air conditioners we had installed were unable to cope with the summer heat, creating a significant safety risk. Once Super Therm® was applied to the exterior of the container, the temperature reduce significantly and the air conditioning units were able to cycle down”.

Christian Crau – Operations Manager, Origin Energy, Adelaide

Tampa Bay – Building with Steel Shipping Containers and Super Therm®

Tampa Armature Works uses Super Therm® ceramic solar heat insulation coating, which is sprayed on both sides of the remaining container walls to prepare the house for heating and cooling loads. Super Therm® is a high-performance, four-part ceramic coating that adheres to the steel surface of the shipping containers. “It really worked,” says Shannon Locklair, project superintendent for the North Charleston house. “We had an open house one day when it was 85 or 90 degrees F out and the air was at least 10 to 20 degrees F cooler inside. This was before we had even installed the windows.”

“The true key to heat protection is preventing heat load. Super Therm® is a 21st century ceramic solar heat insulation coating. The concept is simple: Why slow the transfer of heat into a building when you can just prevent that heat from ever loading onto the building in the first place? If heat is kept off the structure to begin with, that fiberglass insulation becomes more efficient. It’s a change in the way we think about protecting our homes against energy lost “Emissivity is 21st century.”

Consumers should be careful to distinguish between purely reflective coatings and true solar heat insulation coatings. Reflective coatings only perform when clean and will not block all forms of heat, but a coating with heat blocking and reflective qualities will block more than one form of heat.” Super Therm® uses four ceramic compounds to insulation short-wave radiation, IR, and to insulation the conductivity of heat through the surface,” claims Pritchett. “It’s not just a reflective coating.” > Read the full article.

Hepburn Springs, Victoria Container Home “fantastic environmentally“

12 shipping containers successfully converted into residential housing in Hepburn Springs, Victoria and coated with Super Therm® tinted to Desert Tan.

Madeleine McCristal surveys the surrounds from her shipping containers that are protected from solar heat insulation and applied both external and internal.

Madeleine says “I have used Super Therm® over my entire steel building. I am very happy with its performance in regard to keeping the complex cool.”

DryDocks World (Dubai) Super Therm® Container Test Results

In winter 2011 a test was set up at the DryDocks World in Dubai. Two shipping containers were tested in real world environments for 48 hours. The surfaces were not cleaned when tested. See the Case Study pdf.

The study showed the Super Therm® container was on average 5°C cooler inside than the container without Super Therm® See the test >

Summer Container Residence in Italy

Sardinia has a typical mediterranean climate. During the year there are approximately 300 days of sunshine, the average temperature is between 11 to 17°C (52° to 63°F), but in summer the extreme temperature gets up to 36°C (97°F), effectively a desert environment.

Two of the 3 corrugated-steel exteriors of the containers were painted with Super Therm®, a ceramic coating that protects the structure to reduce heating and cooling loads. Super Therm® ceramic coating is a paint mixed with 4 ceramic compounds for application via spray or roller to exterior and interior surfaces. Ceramic coatings are measured by their emissivity – it measures both the ability to reflect heat and the amount of heat that is loaded onto a surface.

Although they installed air conditioning, they have never used it thanks to the Super Therm® ceramic heat insulation coating, if anything, the paint works almost too well, making the containers feel almost like refrigerators at night!

They bought 3 containers – 2 of them they painted with Super Therm®, they finished the paint and could not buy it on this island, so they used normal paint for the third container. The exposure to wind and sun has been the same for all three, all three had the same amount of doors for ventilation, but the ‘normal’ one which we used as bathroom, has been terribly hot by day and by night. The clients said this research might be too spontaneous and empirical, but this was what they have experienced so far. Read More >

Super Therm® works because it insulation the solar heat by reflecting the sunlight and reduces the infrared heat. Since light cannot get in contact with the walls, the walls cannot heat up, which in turn keeps the air inside from heating up during the day. The air inside stays as cool as it is in the surrounding (windy) environment. Since Super Therm® is not like traditional insulation that traps the heat it can work in reverse. The air at night is cooler as it is a desert environment. So it keeps the walls from heating up during the day and by painting the internal walls with Super Therm® keeps the heat generated internally inside the container at night to protect against dropping temperatures.

Redondo Beach Shipping Container House

Eight Intermodal Steel Building Units (containers) were used to add square footage to this $1.6 m home. All containers are coated with Super Therm® on the interior and exterior of the walls, ceilings and floors.

The Redondo Beach container home is owned by Sven and Anna Pirkl. “They not only wanted a residence made out of containers but they were creative and bold enough to push the envelope with me,” notes DeMaria. “It was a match made in heaven,” concurs Sven Pirkl, who along with his wife, an artist, envisioned a modern, loft-style house that was both eco-friendly and budget-minded.” Super Therm® ceramic heat insulation coating helps protect the container from the heat and preserve heat inside in winter.

Super Therm® El Salvador ‘Magic Paint’

In El Salvador, Super Therm® is now known as “pintura mágica”. (Magic Paint). There are approximately 250 containers in a local housing project.

The project is a modular built accommodation using used shipping containers. With urgent need for accommodation, containers allowed the rapid deployment of a new facility, and a relatively low cost, and would actually create great quality to what is currently available in standard constructed buildings.

They can build and deploy these just about anywhere in the country with the use of a well water, solar power lighting and other technologies to make them infrastructure independent.

Enter Super Therm®. The distributor coated a container with Super Therm® and added also an attic ventilation fan to keep air circulating inside.

There was no need to coat inside the unit since the primary element is sun’s radiation and high outside ambient temperatures. On the day of the presentation, a thermometer places outside the container, on the container wall, in the sun, registered 51°C (125°F) while inside the container the temperature remained at shaded ambient of 30°C (87°F). It truly amazed all who experienced it!

The temperature was reduced from 48°C to 30°C inside the container on a 51°C day.

The picture shows the local Minister noting the difference between the temperature on the surface of the painted logo, and the surface of the Super Therm®; of which there was a marked and noticeable difference. They had a standard non-coated container on site as well, and it was so hot you could not even hold your hand on the surface and inside temperatures ranged into the 48°C (120°F) range.

| Container without Super Therm® | Wall | Roof |

| Inside | 48.6°C | 58°C |

| Outside | 48°C | 49°C |

| Container with Super Therm® | Wall | Roof |

| Inside | 30.4°C | 27.8°C |

| Outside | 30.8°C | 30.2°C |

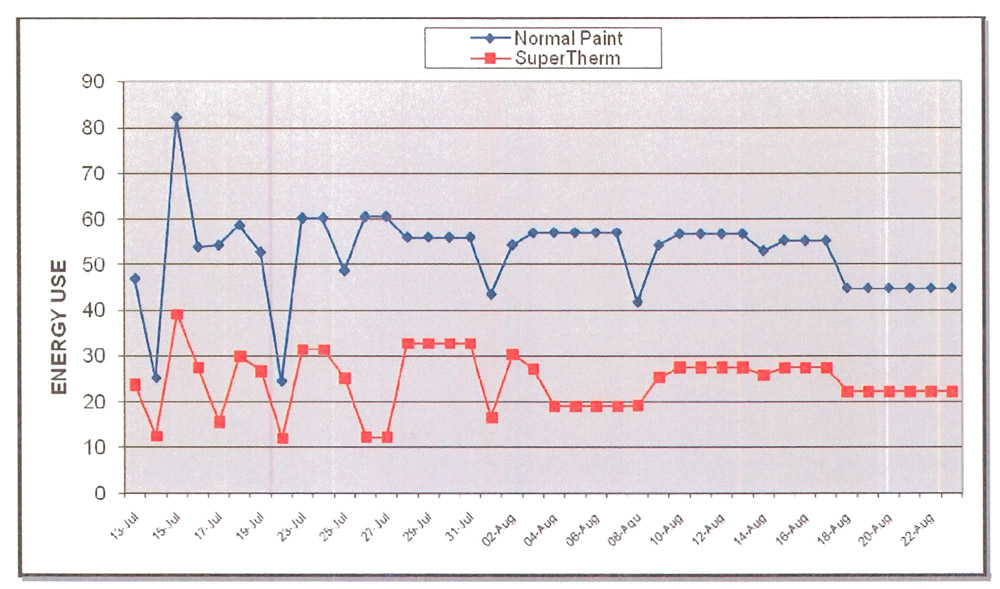

Texas

Reduction

- Conduction related energy loads were reduced

- Internal surface temperatures: 20°C (37°F) Cooler

- Outside Surface Reflectivity: 50% Higher

- Ultraviolet absorption rate: 92% Less

- Internal Moisture levels: 28.5% Dryer

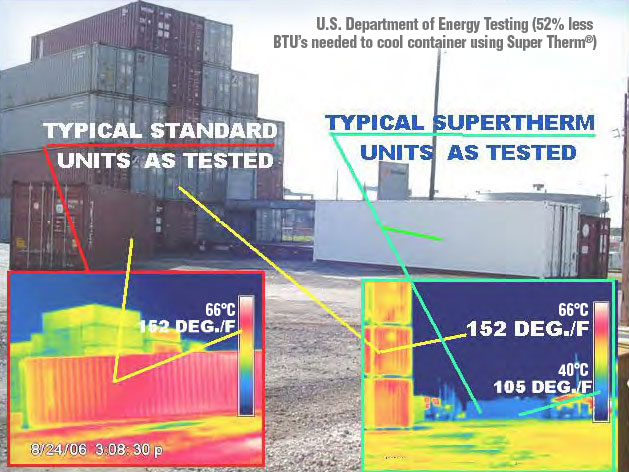

On August 23rd & 24th, 2006 a test was conducted in LaPorte, Texas in accordance with the Florida Energy Conservation Assistance Programs Designation: ECAP-CUL-1-03 Method for Comparing Utility Loads in Structures and Buildings.

The objective of this analysis is to determine the impact of the “As Built Conditions and As Installed Components / Equipment” on the energy producing loads on occupied residential, commercial, government building and other structures. The focus of this procedure is to provide a comparison to known standards for all parties interested in using alternative and conventional conservation products and devices to displaced energy loads. This report reflects the performance characteristics of Super Therm®, as applied to the structures external surfaces, as a possible passive Energy Conservation Measure (ECM) to reduce internal Energy Loads and reduce the Heat Island Effects caused by exposed surfaces in urban areas.

Our data indicated that at the time of this survey the test specimen container inside surface conduction related energy loads were reduced by applying Super Therm® as an Energy Conservation Measure (ECM) to outside surfaces.

Average site weather conditions during the analysis period were as follows:

- High Temperature 36°C (97°F).

- Low Temperature 23°C (74°F)

- Average Wind Speed 2-4.7 knots (3 to 5.5 MPH)

- Average UV intensity 99 A+B

Outcomes:

- Inside container ambient temperature: 12°C (22°F) Cooler

- Thermal conductance to outside environment: 50% Less

- External surface temperature: 26°C (47°F) Cooler

- Internal surface temperatures: 20°C (37°F) Cooler

- Outside Surface Reflectivity: 50% Higher

- Ultraviolet absorption rate: 92% Less

- Internal Moisture levels: 28.5% Dryer

NOTE: Laboratory and Field project results as stated here may vary according to different climate conditions.

Super Therm® Coverage for a shipping container

Each container has 2 sides / 2 ends and the roof (18.9 litres per 5 US gallons pail)

- Standard 20’ x 8’ x 8’ = total area to cover 56.5m2 (+ 15% profile 65m2) – 2 pails (27 litres)

- High cube 20’ x 9.6’ x 8’ = total area to cover 68m2 (+ 15% profile 78m2) – 2 pail (32.5 litres)

- Standard 40’ x 8’ x 8’ = total area to cover 101m2 – 1088 f2 (+ 15% profile 116m2) – 3 pails (48 litres)

- High cube 40’ x 9.6’ x 8’ = total area to cover 122m2 (+ 15% profile 140m2) – 3.5 pails (58 litres)

- Standard 10′ x 8′ x 8‘ = total area to cover 41m2 (+ 15% profile 47m2) – 1 pail (19 litres)

Please allow 15% extra spread rate for the rib contours profile in the container.

Currently we sell full 5 gallon US (18.9 litres) pails. Super Therm® has a coverage of 40-45 m2 per pail depending on application. Note: if container has rust it needs to be thoroughly cleaned and we suggest a coat of Rust Grip® before you apply Super Therm® or a rust converter. For the ultimate protection then apply Enamo Grip over the top as the perfect tough protection. Contact us below if you wish to purchase Super Therm® for your shipping container project.

20′ Standard Container – 2 pails

| Dimension | External Metric | External Imperial | Internal Metric | Internal Imperial |

|---|---|---|---|---|

| Surface area (no floor) | 56.5 m2 (+15% profile 65m | 608 f2 | – | – |

| Length | 6.06 m | 20′ (19’4″) | 5.89 m | 19’4″ (19’3″) |

| Width | 2.44 m | 8′ (7’9″) | 2.35 m | 7’8″ (7’9″) |

| Height | 2.59 m | 8’6″ (7’10”) | 2.39 m | 7’10” (7’8″) |

| Door Width | 2.34 m | 7’8″ (7’5″) | 2.26 m | 7’5″ (7’4″) |

| Door Height | 2.26 m | 7’5″ (7’4″) | 2.24 m | 7’4″ (7’3″) |

| Cubic Capacity | 33.2 m³ | 1,172 cu ft (33.2 m³) | 33 m³ | 1,165 cu ft (32.7 m³) |

| Max Gross Weight | 30,000 kg | 66,139 lbs | – | – |

20′ High Cube Container – 2 pail

| Dimension | External Metric | External Imperial | Internal Metric | Internal Imperial |

|---|---|---|---|---|

| Surface area (no floor) | 68 m2 (+15% profile 78m2) | 729.6 f2 | ||

| Length | 6.06 m | 20′ (19’4″) | 5.89 m | 19’4″ (19’3″) |

| Width | 2.44 m | 8′ (7’9″) | 2.35 m | 7’8″ (7’9″) |

| Height | 2.89 m | 9’6″ (8’10”) | 2.69 m | 8’10” (8’7″) |

| Door Width | 2.34 m | 7’8″ (7’5″) | 2.26 m | 7’5″ (7’4″) |

| Door Height | 2.58 m | 8’6″ (8’5″) | 2.56 m | 8’5″ (8’4″) |

| Cubic Capacity | 37.4 m³ | 1,320 cu ft (37.4 m³) | 36 m³ | 1,272 cu ft (35.9 m³) |

| Max Gross Weight | 30,480 kg | 67,200 lbs | – | – |

40′ Standard Container – 3 pails

| Dimension | External Metric | External Imperial | Internal Metric | Internal Imperial |

|---|---|---|---|---|

| Surface area (no floor) | 101 m2 (+15% profile 116m2) | 1088 f2 | ||

| Length | 12.19 m | 40′ (39’4″) | 12.01 m | 39’4″ (39’5″) |

| Width | 2.44 m | 8′ (7’9″) | 2.35 m | 7’8″ (7’9″) |

| Height | 2.59 m | 8’6″ (7’10”) | 2.39 m | 7’10” (7’8″) |

| Door Width | 2.34 m | 7’8″ (7’5″) | 2.34 m | 7’8″ (7’5″) |

| Door Height | 2.26 m | 7’5″ (7’4″) | 2.27 m | 7’5″ (7’5″) |

| Cubic Capacity | 67.6 m³ | 2,387 cu ft (67.6 m³) | 66.7 m³ | 2,362 cu ft (66.5 m³) |

| Max Gross Weight | 30,480 kg | 67,200 lbs | – | – |

40′ High Cube Container – 3.5 pails

| Dimension | External Metric | External Imperial | Internal Metric | Internal Imperial |

|---|---|---|---|---|

| Surface area (no floor) | 122 m2 (+15% profile 140m2) | 1305 f2 | – | – |

| Length | 12.19 m | 40′ (39’4″) | 12.01 m | 39’4″ (39’5″) |

| Width | 2.44 m | 8′ (7’9″) | 2.35 m | 7’8″ (7’9″) |

| Height | 2.89 m | 9’6″ (8’10”) | 2.69 m | 8’10” (8’7″) |

| Door Width | 2.34 m | 7’8″ (7’5″) | 2.34 m | 7’8″ (7’5″) |

| Door Height | 2.58 m | 8’6″ (8’5″) | 2.69 m | 8’10” (8’7″) |

| Cubic Capacity | 76.4 m³ | 2,700 cu ft (76.4 m³) | 75.8 m³ | 2,681 cu ft (75.3 m³) |

| Max Gross Weight | 30,480 kg | 67,200 lbs | – | – |

10′ Standard Container – 1 pail

| Dimension | External Metric | External Imperial | Internal Metric | Internal Imperial |

|---|---|---|---|---|

| Surface area (no floor) | 40.62 m2 (+15% profile 47m2) | 438 ft2 | – | – |

| Length | 3.05 m | 10′ (9’10”) | 2.83 m | 9’3″ (9’10”) |

| Width | 2.44 m | 8′ (7’9″) | 2.35 m | 7’8″ (7’9″) |

| Height | 2.59 m | 8’6″ (7’10”) | 2.39 m | 7’10” (7’8″) |

| Door Width | 2.34 m | 7’8″ (7’5″) | 2.34 m | 7’8″ (7’5″) |

| Door Height | 2.26 m | 7’5″ (7’4″) | 2.27 m | 7’5″ (7’5″) |

| Cubic Capacity | 15.9 m³ | 562 cu ft (15.9 m³) | 14.5 m³ | 513 cu ft (14.5 m³) |

| Max Gross Weight | 15,240 kg | 33,540 lbs | – | – |

Affordable shipping container corrosion protection

Shipping containers are typically made of steel, which is highly susceptible to corrosion. Firstly the structure of the container is jeopardised and also the lifespan of the container’s use is limited. Rust Grip® is the perfect solution before you consider Super Therm® on your container if you want to truly protect the surface for more than 20 years. Overall, it’s important to take measures to prevent and treat corrosion on shipping containers to ensure their longevity, safety and aesthetic appeal.

Before Rust Grip® is applied. Poor surface quality, corrosion and at risk of corrosion holes in future.

Recommended coating system for shipping containers

The SPI Coating System applied to the shipping containers consists of the following: After thorough pressure clean and drying, Super Therm® is applied directly to the exterior walls and roof of the container, and HSC® Coating (recommended) and Super Therm® applied directly to the interior walls and ceiling of the container.

In the real world environment with factors of condensation, air infiltration, moisture absorption, and thermal bridges, the SPI Coating System provides a true heat load management benefit for the shipping containers in cool to hot environments.

The SPI Coating System provides solar heat insulation protection against radiation heat transfer and conductive heat transfer, insulation the absorption of moisture, air infiltration, condensation, and mould and mildew, and is a fire resistant coating with zero flame spread and zero smoke.

SPI Coatings are pleased to be a part of and to support your efforts to develop energy efficient and affordable structural systems for use in home and commercial construction using shipping containers.

- Rust Grip® – Can applied directly over rusted metal surfaces or existing paint, with no sandblasting required. As a three-coats-in-one system, Rust Grip® acts as a primer, intermediate, and topcoat that strengthens to 6780 psi (473 bar) when fully cured. (Almost twice as hard as concrete – 3500 psi by comparison). With a 15,000 hour salt spray test rating, Rust Grip® is one of the most effective anti-rust/anti-corrosion coatings you can use on shipping containers. Especially in salt air, marine, and coastal environments.

- Enamo Grip® – A high performance, two-part architectural grade polyurethane enamel top coat that is an excellent choice for shipping containers / conex boxes when a high quality architectural grade finish is needed. It has excellent gloss retention and is highly resistant to UV, scuffing, and chalking . Enamo Grip is self leveling and can be tinted to any colour.

- Super Therm® – Our heat reflective ceramic coating can be used for a wide range of projects.

Container Condensation Control

Condensation on a container roof and walls is due to the fact the underside of the roof’s substrate becomes colder than the opposite surface. If SUPER THERM® Ceramic Solar Heat insulation Coating is applied on top of a container or verandah, facing the sun and reducing any heat load into the metal this solves one part of the challenge.

The other part is also using SUPER THERM® or HSC on the underside to stabilise ambient temperatures on the inside of the substrate as well.

In airflow environments or locations where the underside remains near ambient the better the position to control condensation. When the warm air hits the substrate and sets, it cools and when it cools, it cannot hold the moisture and it shows as condensation on the side of the warm air.

As warm air cools, it drops out it’s moisture. Because the heat has transferred through the substrate it presents as moisture on the cool side. Heat is drawn to cool.

In all situations, if there is a 5 degree difference between ambient and a surface with the surface being cooler, you will have condensation.

So, it is a situation where you check the temperatures of ambient and the surface to see if you have a problem with condensation.

Then if the difference between the ambient and the surface is wide you have to start using a product like Hot Pipe Coating or Hot Surface Coating to help control the condensation because you need thickness to keep the ambient (hot/humid) temp away from the surface temp of the unit, roof or wall.

When you get over a 20 degree difference between the interior and exterior of a wall, you may need some thickness of insulation to prevent condensation like HSC.

The goal is to reduce the warm air from setting on the surface of anything cool, SUPER THERM® helps to throw off the radiation during the day by using emissivity to release the warmth off the surface and heat load. It also slows down the escape of heat during the night. Application on the opposite surface wth SUPER THERM® prevents the substrate being extremely cool which therefore prevents the large temperature differences that convert into moisture and condensation.