Super Therm® Case Studies

Super Therm® is used around the world so you can be sure its proven, scrutinised and tested with outstanding results

Super Therm® has a 70% market share in Japan, is used widely in Europe, South East Asia, the Middle East and Australia. Through 20+ years of application and testing, Super Therm® has proven to be the most effective solar heat block and weatherisation coating on the market.

Super Therm® is a 20-50% energy reducing solution! (Industry testing)

World wide markets include:

Asia: Japan • China • Taiwan • Korea • Malaysia • Singapore • Indonesia • India

Europe: Italy • Germany • France • Belgium • Netherlands • Turkey • Greece • Spain • Russia • Ukraine

Middle East: Saudi Arabia • UAE • Oman

South America: Venezuela • Colombia • Brazil • Argentina • Chile

Central America: Mexico • Panama • Puerto Rico • Costa Rica

Africa: Egypt • Nigeria • Tanzania • South Africa • Angola

Australia • New Zealand • Mexico • Canada • U.S.A.

Sony Koda 75% energy reduction

Above: Nissan Factory, Yokahama, Japan: 200,000m2

| Application of Sony Koda | May | June |

| Before Super Therm® applied | 3,767 KW | 5,647 KW |

| After Super Therm® applied | 519 KW | 1,896 KW |

| TOTAL KW REDUCTION | 87% | 67% |

Source: Daiko Shokai, Japan | See more Japanese Case Study results (pdf)

Vodafone Mobile Phone Containers, Turkey

For transmitting the reception signal for mobile phones in Turkey, an air-conditioned container with electronic equipment is used. The problem is that the containers can overheat with extreme outside temperatures (30°C+) with the result that the equipment will malfunction or even break down.

One of the parameters is that the container had to have a constant inside temperature of 24°C that could often not be reached with the air conditioner that was used.

The problem is that there are significant electricity costs for cooling the container to the right, constant temperature of 23°C. The containers are 2 x 2 x 3 meters, which are 24m2 for the entire container, bottom excluded.

Treat the container with Super Therm® on the outside to reflect the direct sunlight, so that the air-conditioner can reach the inside temperature of 23°C more easily and that eventually energy reduction will occur.

Conclusions: Inside temperature of 23°C was reached. An average energy reduction of over 50% was achieved. I

30 years of proven solar heat block coatings success

K-TECH is a manufacturing facility located in Grainfield, Western Kansas, USA. The climate is very severe with -21°C (-5°F) in winter with snow and ice and 38°C (100°F) in summer with sand-storms and very strong solar radiation.

Super Therm® was originally applied to a factory roof of K-TECH in 1989. It was inspected at tested for durability and performance on July 10, 2019. Over 33 years later: NO deterioration; NO failures; NO loss of performance; NO corrosion. See more >

Reducing the Air Conditioning Load in Japan

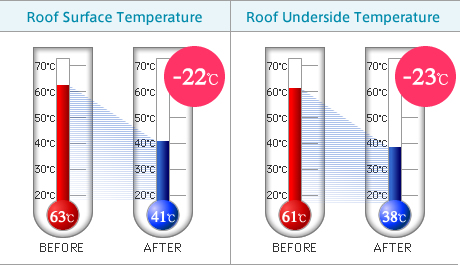

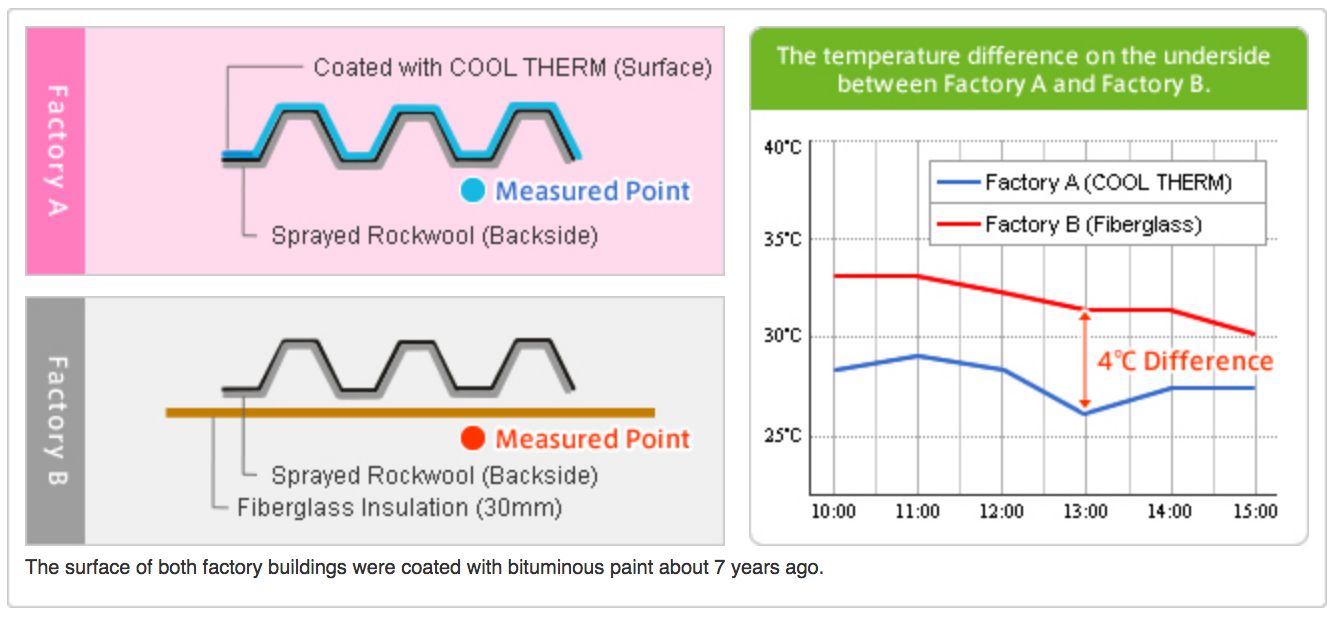

S Corporation was one of the first manufacturers who obtained ISO14001, and they have been active in the environmental and green manufacturing process. They are engaged in the CO2 reduction to fight global warming. Super Therm® was selected as a part of their activities to reduce CO2 by reducing the energy consumption of air-conditioners.

The underside temperature of Factory A with Super Therm® was 4 to 5℃ lower than that of Factory B with traditional materials.

| Energy Reduction Amount | $134,436 Australian dollars (11.05 million Yen) per year |

| Pay back period | 1.06 years |

Result: The initial cost difference was paid off in about one year with Super Therm® energy reduction effects.

Source: Daiko Shokai, Japan | Other Japanese Super Therm® Case Studies PDF

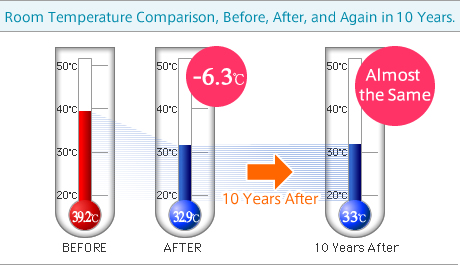

The same room temperature effect after 10 years

Before the application there were days when the room temperature in the 2nd floor exceeded 37 to 40℃, but after the application the room temperature was reduced to 33℃, and the work environment was improved. The room temperature reduction effect is maintained at the same level even after 10 years.

The room temperature measured in August 1996, right after the application was 32.9℃ when the outside temperature was 36℃. Ten years later in August 2006, the room temperature was still 33℃ when the outside temperature was 36℃. Super Therm® maintains the same temperature reduction effect after 10 years.

Source: Daiko Shokai, Japan | Other Japanese Super Therm® Case Studies PDF

US Air Force Renewable Energy Symposium

Super Therm® featured at US Air Force Renewable Energy Symposium June 28th & 29th, 2011 at the US Air Force conducted a Renewable Energy Symposium in Tucson, Arizona. The aim was to continue their leadership in developing and using renewable energy to reduce its reliance on fossil fuels.

Super Therm® Cool Roof Restoration System was featured as an Innovative Use of Ceramic Coatings to Alter the Approach to Building Heat Gain.

One day prior to the symposium and presentation Super Therm® was applied to the exterior of a typical metal building on the US Air Force base that did not have any traditional insulation or drop ceilings. The days preceding the conference and during the conference had ambient temperatures ranging from 43°c to 45°C (111° to 113°F).

Prior to the presentation and demonstration all air conditioning was shut off for 3 days in order to accurately determine the effectiveness of the Super Therm® in blocking the heat load onto the metal skin of the building.

After 3 days in 43°c to 45°C desert heat with no insulation or air conditioning the interior of the metal building coated with Super Therm® was 29°C (85°F) of the locked metal building.

After the classroom presentation nearly 200 attendees were bussed to the test site and were asked to touch the exterior side. They we impressed to see that the exterior temperature of the Super Therm® coated building was the same as the ambient temperature while the uncoated buildings were over 21°C (70°F) higher.

The doors to the building were then opened and the attendees walk in and around the building. With nearly 60 people in the building and the doors wide open in the desert heat the ambient temperature in the building was an astounding 29°C.

Source: Protecall. For more information contact NEOtech Coatings Australia about this astounding solar heat block coating.

Extreme Arizona temperatures protect the public at Hoover Dam

Super Therm® (Solar Heat Block), Rust Grip® (Rust Prevention) and Enamo Grip (Strong Sealant) coatings selected for SSPC E. Crone Knoy Award. Recognized for Innovative Coating Performance at Hoover Dam Bypass Bridge – Colorado River Bridge.

After extensive testing, the SPI Coatings were selected for the railings surrounding the observation deck on the Bridge, which expects 3 to 5 million visitors each year. No other coatings could produce the level of corrosion protection, ease of application, and radiant heat reduction on the railings demonstrated by the SPI Coatings.

A very unique coating system was used on the project call Super Therm®. This product reflects 96.1% of radiation from the sun. That is why the Federal Highway Department chose this product.

The extreme temperatures of the Arizona/Nevada desert averages 35 to 43°c (95 to 110°F) on most days. The railings that visitors touch are just too hot for skin. Super Therm® as the core solar heat block coating has completely cooled the thermal temperature of the railings and allowed visitors to safely touch.

Read the case study pdf

Super Therm® on a Florida Motorhome RV

- Average internal temperature improvement was 5.6°c – 12%

- 2 hours to pressure clean the roof the day before and fully dry

- 4 hours for two employees to apply the coating 87m2 by roller – 2 pails of Super Therm®

- The exterior surface temperature was 73°c…after application dropped to 30°c (59% improvement)

- Roof surface temperature of a similar mobile home with a white elastomeric paint was 51.6°c

- The motor home owner reported that she had not turned on her air conditioning since the day the roof was coated

- SJHP’s assessment is that Super Therm® works well and meets their purpose and budget. It was relatively easy to apply and does not require significant application skills, other than normal diligence and care. They were very impressed with the immediate temperature changes after application.

Read the full story

Sustainable Houseboat in France

Aqua Lodge has completely self-sufficient boat houses in Guadeloupe. The boat lodges are 80m² and built to accommodate 4-6 people. The lodges are eco-friendly as they are run on solar energy and emit no pollutants. Due to the location of the houseboats and the need to keep the electricity to a minimum the owners were looking for a way to decrease the effects of the solar heat. It required 2 layers by roller of Super Therm® that were applied after after the roof was cleaned.

Results

After application of Super Therm®, with an ambient temperature of 30.1°c a reading of 42.7°c was taken on the untreated surface while the reading on the Super Therm® surface was 30.3°c. (30% reduction in surface temperature)

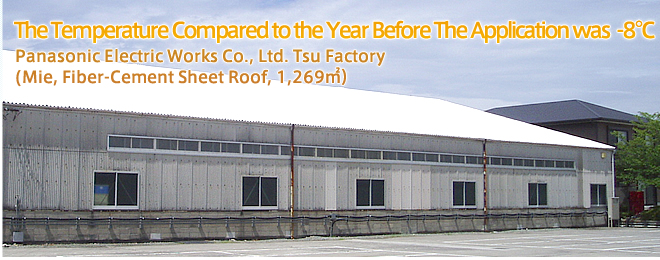

Improving the Work Environment

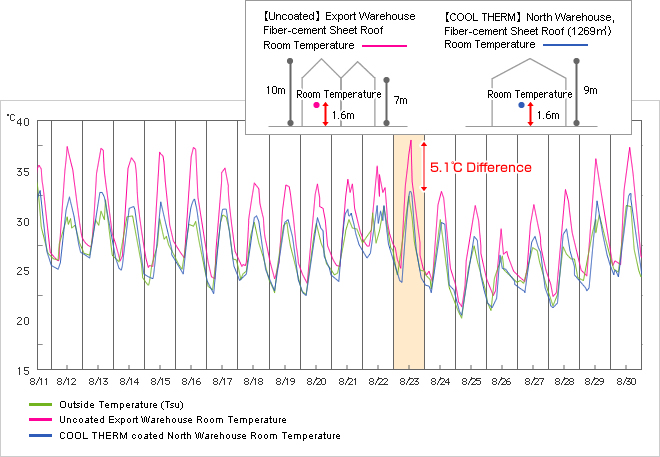

The warehouse was hot inside due to the heat entrance from the roof in summer, and they were looking for a solution to improve the work environment. Super Therm® (Cool Therm in Japan) was selected to reduce the room temperature and to improve the work environment.

In the comparison with the uncoated building (export warehouse) with the same building structure, the max. room temperature reduction was 5.1℃. The workers recognised the great effect, as well, so they are planning to apply Super Therm® to the export warehouse where they measured the uncoated result this time.

They record the room temperature of the same building on a constant basis, and according to their records the temperature reduction compared to the year before the application was -8℃ (Max).

Source: Daiko Shokai, Japan | Other Japanese Super Therm® Case Studies PDF

Super Therm® on Poultry Houses

- Fact: Reduced attic temperature by 16.7°C (30 F) – Benefit: Death rate of chickens dropped by 75%

- Fact: Chickens were heavier at the end of growth season – Benefit: more case value per bird

- Fact: Current insulation materials become loaded with moisture form condensation and must be replaced every 5 years. Super Therm® eliminated condensation and will perform for 20 years without concern for re-insulation – Benefit: Reduces the cost of re-insulation 4 times over 20 years of the life of the house, insulation materials and labour savings.

More on Poultry Barns and Chicken Sheds