Super Therm® Testing & Results

Independent Testing Results Globally for Super Therm®

- USA: Thermophysical Properties of Super Therm® Coating Testing

- Japan: Japanese Institute of Standards for Super Therm®

- Russia: Super Therm® Russian Academy Science Reflection testing

- NASA Space Flight Center Testing of Super Therm®

- Florida: Florida Energy Office Super Therm® Testing

- Denver: Florida Energy Office Super Therm® Testing

- Texas: Florida Energy Office Super Therm® Testing

- Energy Star: Super Therm® to other reflecting coatings on the market

- ASTM Range of Approvals for Super Therm®

- USDA: Food Safety and Inspection Service Approval for Super Therm®

NOTE: Laboratory and Field project results as stated here may vary according to different climate conditions.

Work towards zero emissions; reduce your heat load coating

Achieving Coating Energy Efficiency Standards and looking towards Zero Carbon emissions with coatings, Super Therm® will get you there!

- Super Therm® has only 0.559W/m2K of heat conduction with just a 250 micron application.

- Super Therm® offers a heat conduction of just 4BTU/sf/hr. ASTM E1269 BTU Conductivity testing and results.

Super Therm® Tech Sheet

A product like Super Therm® seems too true to believe so naturally its gets far more scrutiny because of its true claims…yet it is that good!

Super Therm® keeps passing testing with flying colours…better than anything else on the market when you compare apples with apples. Super Therm® is developed and manufactured in the USA and the test results show extensive success in independent labs and on site with case studies showing great results around the world including Japan, Russia, China and the USA.

Super Therm® is a water-borne system using high performance aliphatic urethanes, elastomeric acrylics, and resin additives that produce a tough, flexible coating film. Designed for performance and durability, Super Therm® contains four (4) unique ceramics to block up to 95% of solar heat load from visual light, ultra violet, and infrared wavelengths. Super Therm® is a flexible membrane with low permeability that can greatly reduce expansion and contraction of metal by eliminating thermal shock and that can prevent corrosion and surface deterioration.

Key Super Therm® Heat Block Testing

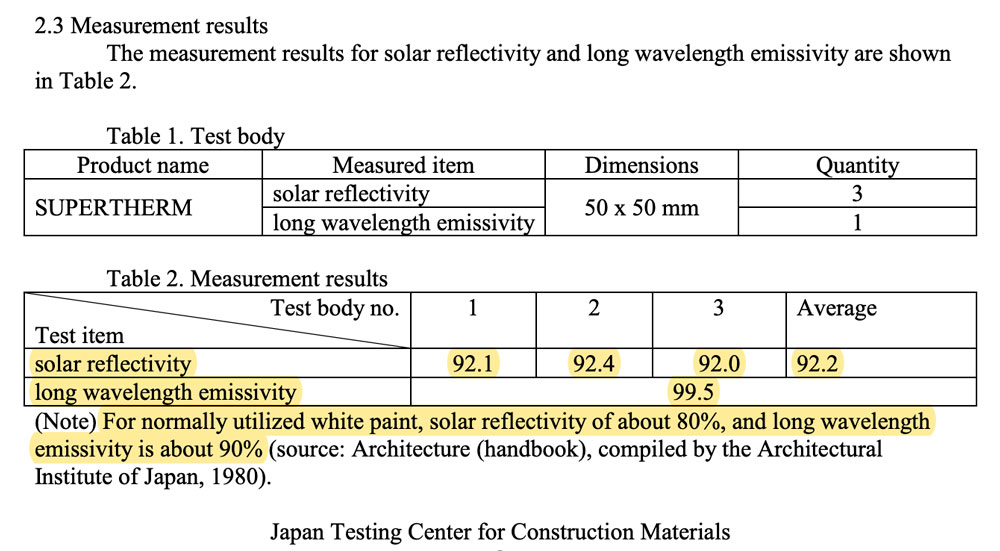

Japan: Japanese Institute of Standards

Cosmo Trade and Services – Japan Testing Centre for Construction Materials. JIS (Japanese Institute of Standards) A 5759 Reflectivity of Light and Radiation for Short Wave (Visual) and Long Wave (Infrared).

- Super Therm blocked Short Wave block – 92.2% (Visual light heat)

- Super Therm blocked Long Wave block – 99.5% (Infrared heat)

Test Results – PDF

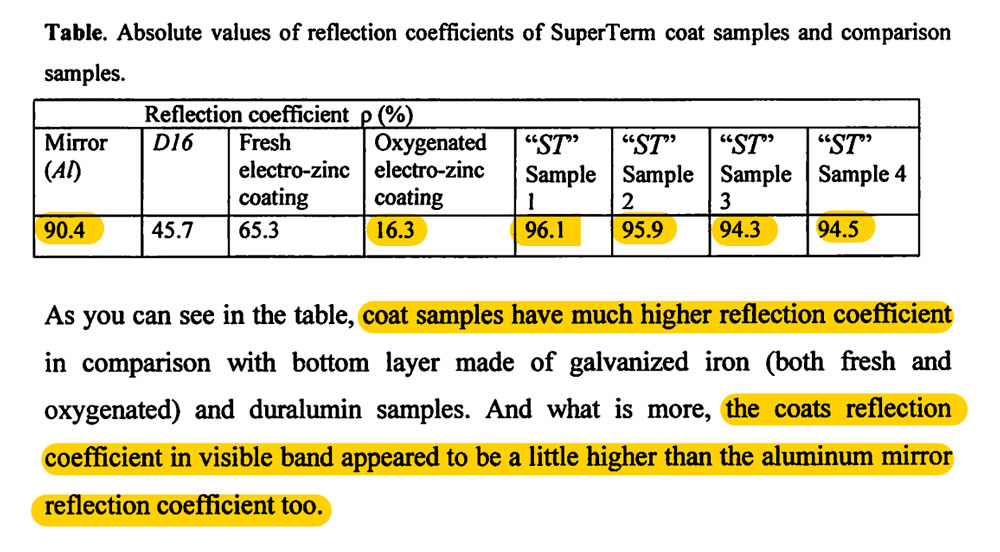

Russia: Super Therm® Russian Academy Science Reflection testing

Testing by the Russian Academy of Sciences on Super Therm® showed how it outperformed a polished mirror in testing results. Research of the coat samples of Super Therm® for reflection of visible and infra-red bands.

Report abstract: It emerged that specular reflection coefficients for all Super Therm coat samples and base material – galvanised iron – practically do not reflect the light specularly in all visible frequency band, where diffused reflection of Super Therm® coat appeared to be very effective for diffusion of visible light falling on energy object.

- Super Therm blocked Short Wave block – 95% Avg (Visual light heat see below)

Test Results – PDF

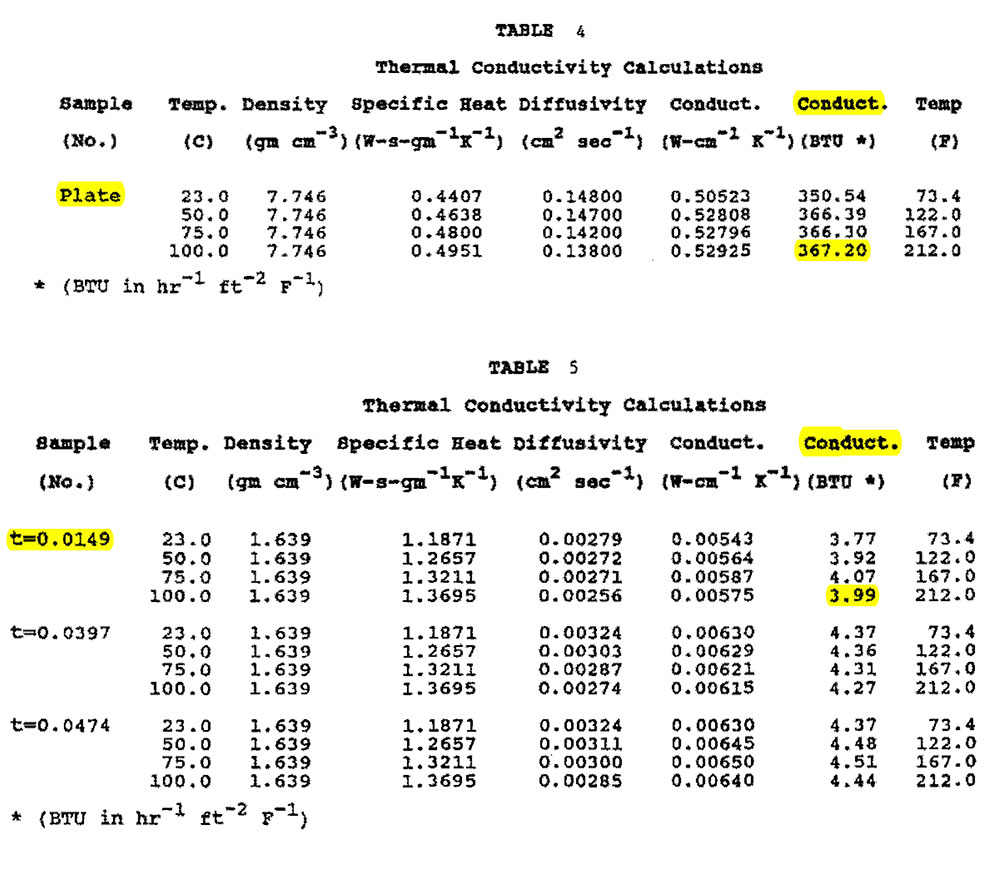

USA: Thermophysical Properties of Super Therm® Coating Testing

A gallon of Super Therm® coating and a metal plate were submitted for thermophysical property testing for a room temperature to 100°c. The test was ASTM E1269 and thermal diffusivity. Super Therm® temperatures were tested at 23°C, 50°C, 75°C and 100°C.

Super Therm® blocked the BTU heat load from 367 down to just 4 BTU at 100°C. Metal surface not coated allowed 367.20 (108 watts) to enter a storage tank per m2 per hour. Metal coated with one coat of Super Therm® allowed only 4 BTU (1 watt) to enter per m2 per hour. It was noted that the conductivity of the paint is independent of the surface to which it is applied – that is, the conductivity of the paint is the same on a metal or a concrete surface.

It should be noted that the conductivity of the paint (Super Therm) is independent of the surface to which it is applied, that is, the conductivity of the paint (Super Therm) is the same on a metal or concrete surface.

Test Results – PDF

NASA Flammability Test

NASA Space Flight Center Testing of Super Therm®. Class A – no flame spread!

In this report NASA tested and classified Super Therm® as a Class “A” rated coating having -0- flame spread in the burn test. Flame spread is rated from “0” being the best to over “100” as being the worst at contributing to flame or fire.

Super Therm® rated excellent in absolutely no contribution to flame or fire. This is an unusual rating for any paint product as most will score from a low of 15 up to 88. The “A” classification is the highest classification that can be achieved. This result definitely shows the quality of Super Therm®.

NASA is currently so impressed with Super Therm® that they are now establishing testing in additional areas of need for the space center. These needs involve not only their facilities but other classified areas.

Test Results – PDF

Florida Energy Office Super Therm® Testing

Super Therm® has been thoroughly tested by the Florida Energy Office for energy efficient reduction in three locations, Florida, Denver and Texas. It has also passed testing for:

- Exposure to UV, elevated temperature and humidity – passed

- Water Vapour transmission – passed

- Resistance to cracking on metal or rubber type materials – passed

- Tensile Strength – passed

- Flame Spread and smoke generation – passed

- Structure Steel Fire Curve – passed

- Thermal conductivity test – passed

- Salt spray only – 450 hours – passed

- Fungal growth or soil and dirt accumulation on paint film – passed

- Abrasion resistance of organic coatings – passed

- Toxic offgassing – none – passed

- Reflectivity of sunlight on window or coating film – passed

- Environmentally safe and safe for use around animals – passed

- Approved and accepted as energy star partner for reducing energy – passed

Florida Solar Heat Block Coatings Test – Florida Energy Office

On February 10th & 11th, 2003 a test was conducted on Super Therm® Solar Heat Block Coating, applied to a residential home roofing system located in Dade County, Florida in accordance with the State of Florida Energy Office / Energy Conservation Assistance Programs Designation: ECAP-CUL-1-99.

As installed, at the time of this testing, the Super Therm® Roof Coating System proved to be an effective Energy Conservation Measure (ECM) that produced a reasonable simple pay back of approximately 2.2 years on this particular project. This would indicate that it’s application could be fundable with Federal and / or State of Florida Energy Grant Dollars where applicable. Note: Results may vary in different conditions and locations.

Full report >

NOTE: Laboratory and Field project results as stated here may vary according to different climate conditions.

Denver Solar Heat Block Coatings Test – Florida Energy Office

On July 19th & 20th,2004 in accordance with the State of Florida Energy Office / Energy Conservation Assistance Programs Designation: ECAP-CUL-1-03 Method for Comparing Utility Loads in Standard Constructed Buildings in Denver, Colorado. The test was over 24 hours between Super Therm® and standard Latex Paint with 2 identical controlled structures. Reports showed it took 30% less energy to heat or cool the building with Super Therm® and moisture levels were reduced. Note: Results may vary in different conditions and locations.

Full report >

NOTE: Laboratory and Field project results as stated here may vary according to different climate conditions.

Super Therm® Field Retrofitted Shipping Containers Test (pdf – 1.6mb)

On August 23rd & 24th, 2006 a test was conducted in LaPorte, Texas in accordance with the Florida Energy Conservation Assistance Programs Designation: ECAP-CUL-1-03 Method for Comparing Utility Loads in Structures and Buildings.

Utilising shipping containers, the data indicated that at the time of the test specimen container inside surface conduction related energy loads were reduced approximately 46 to 52% by applying Super Therm® as an Energy Conservation Measure (ECM) to outside surfaces.

- Conduction related energy loads were reduced approximately 46 to 52%

- Internal surface temperatures: 20°C (37°F) Cooler

- Outside Surface Reflectivity: 50% Higher

- Ultraviolet absorption rate: 92% Less

- Internal Moisture levels: 28.5% Dryer

Full report >

NOTE: Laboratory and Field project results as stated here may vary according to different climate conditions.

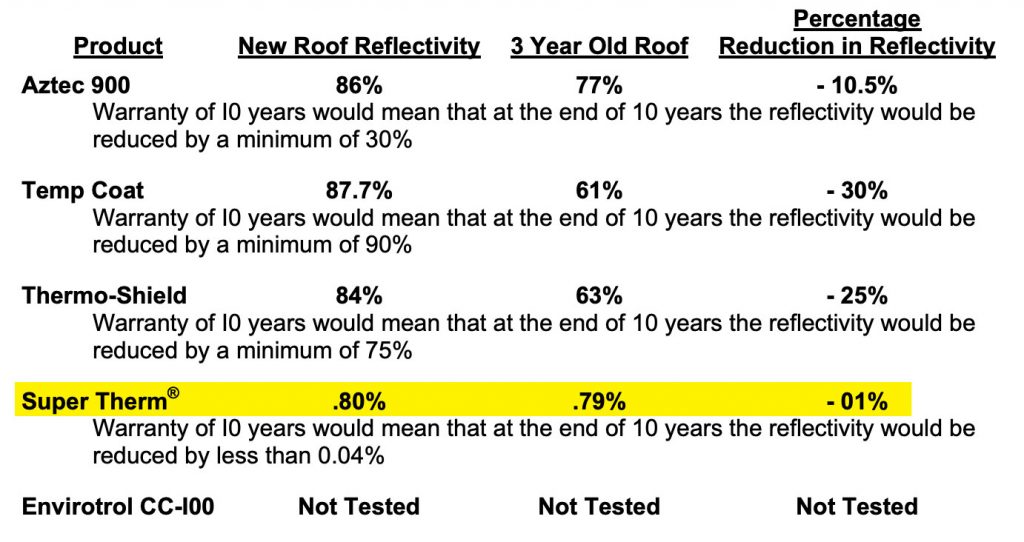

Comparison of Super Therm® to other reflecting coatings on the market

When tested for Energy Star Program

In the government testing procedures on the products by Insulating Coatings Corporation, Temp-Coat Brand Products, LLC, and SPM Thermoshield, Inc. dba Roof Guardian when tested for Energy Star Program, the testing was performed to demonstrate the reflectivity of a new roof and of a three-year old roof to determine the reduction in reflectivity/performance and loss of insulation effectiveness.

See the original report of the Energy Star Program at www.energystar.gov.

This comparison testing shows very clearly that Super Therm® is the best coating on the market to maintain its insulation ability over the years. The other coatings must be reapplied to maintain any insulation ability. Super Therm® does not have to reapplied.

Full report pdf

Super Therm® ASTM Test Listing (pdf – 58kb)

American Society of Testing and Materials (ASTM)

- ASTM C 236-89(93) – C1363; Standard Test Method for Thermal Performance of Building Materials and Envelope Assemblies by Means of a Hot Box Apparatus. Thermal Transmittance/Conductance

- Fibreglass board having 0.52 conductance (BTU/square foot/hour/F)

- Super Therm® at 10 mil dry having 0.31 (BTU/square foot/hour/F)

- One coat of both sides of wall, each coat at 10 dry mils having 0.21 (BTU/square foot/hour/F)

- ASTM B-117 / D-1654; Salt Spray (Fog); Results; Passed 450 Hours

- ASTM C-411; High-Temperature Surface Performance; Results; no warping, cracking, de-lamination, or colour change

- ASTM C-1371; Emissivity; Results; 0.91%

- ASTM C-1371; Reflectivity; Results; 0.85%

- ASTM D-412; Tensile Strength; Results; 444 psi

- ASTM E 1461; (92) Thermal Diffusivity/Conductivity by Flash Method Standard BTU (Infrared) flow through metal plate being 367.20 reduced with one coat of Super Therm® to 3.99 – 99.5%

- ASTM 0-522; Mandrel Bend; Results; 1″ (25mm) bend, ¼” (6mm) bend

- ASTM D-1653; Water Vapour Permeability; Results; Passed

- ASTM D 3273-82T / D 327 4; Fungal Resistance; Results; Passed.

- ASTM D-4060; Abrasion Resistance (Taber test); Results; 0.06g

- ASTM D-6904; Resistance to Wind Driven Rain for Exterior Coatings (Fed Spec TT-C-5558 )

- ASTM D-7088; Resistance to Hydrostatic Pressure for Coatings (Fed Spec TT-C-555B)

- ASTM E-84 (NFPA 255); Flame Spread / Smoke Developed; Results; Class “A” Rating

- ASTM E 84-89; Flame Spread/ Smoke Developed; Results; Flame Index “0”, Smoke Index “0”

- ASTM E 108 Flame Spread over Pitch Roof Structure

- ASTM E-96; Water Vapour Transmission; Results; Less than .01, Perms 8.8

- ASTM E 903-96; Spectral Reflectance 80% – only 0.6% loss in performance over three years in field

- ASTM G 53; 1000 hours UV exposure

- ASTM E 1269; Heat Capacity by Differential Scanning Colorimeter

- ASTM D 4541; Standard Method for Pull-off Strength (Result: 191psi – 13.37 bar strength)

- ASTM D 794; Determine Wet Adhesion Results. Wet adhesion to Galvanised Steel (Result: 3.6 – Required ≥ 2.0)

China Centre for Technical Testing

- GB/T 1771-91 Resistance to Salt Fog (2000 hours) – passed

- GB/T 1866-88 Manual Ageing (2000 hours) – passed

- GB/T 10834-88 Resistance to Salt Water (1000 hours) – passed

- GB/T 5219-85 Adhesion (Pulling Apart Method) (6.72MPa) – passed

- GB/T 1733-93 Boiling Water Immersion (8 hours) – passed.

Other Testing Results

- International Maritime Association: IMO A.653.(16) Flame Spread Test passed for Bulkhead, wall and ceiling linings.

- NASA (National Aeronautic and Space Administration) NASA 8060.1 B/C Flammability Test – passed, Class A with “0” flame spread

- NASA 8060.1 C Toxic Off-gassing Test “K” rating for “0” off gassing

- ABS (American Bureau of Shipping) testing, IMO (International Maritime Org) and US Coast Guard Approval. MSC 41, Smoke Toxicity – passed

- ASTM G53 – Practice for Operating Light- and Water-Exposure Apparatus (Fluorescent UV-Condensation Type) for Exposure of Nonmetallic Materials (Withdrawn 2000)

- ASTM E96 – Standard Test Methods for Water Vapor Transmission of Materials

- ASTM D522 – Standard Test Methods for Mandrel Bend Test of Attached Organic Coatings

- ASTM D412 – Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension

- ASTM D1653 – Standard Test Methods for Water Vapor Transmission of Organic Coating Films

- ASTM E 84-89 – Standard Test Method for Surface Burning Characteristics of Building Materials

- ASTM E 119 – Standard Test Methods for Fire Tests of Building Construction and Materials

- ASTM C 177 – Standard Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the Guarded-Hot-Plate Apparatus

- ASTM C 411 – Standard Test Method for Hot-Surface Performance of High-Temperature Thermal Insulation

- ASTM E1269 – Standard Test Method for Determining Specific Heat Capacity by Differential Scanning Calorimetry

- ASTM E1461-92 – Standard Test Method for Thermal Diffusivity of Solids by the Flash Method

- ASTM D1654 – Standard Test Method for Evaluation of Painted or Coated Specimens Subjected to Corrosive Environments

- ASTM D3274 – Standard Test Method for Evaluating Degree of Surface Disfigurement of Paint Films by Fungal or Algal Growth, or Soil and Dirt Accumulation

- ASTM D4060 – Standard Test Method for Abrasion Resistance of Organic Coatings by the Taber Abraser

- ASTM E-903-96 – Standard Test Method for Solar Absorptance, Reflectance, and Transmittance of Materials Using Integrating Spheres

- ASTM E-1918 – Standard Test Method for Measuring Solar Reflectance of Horizontal and Low-Sloped Surfaces in the Field

- JIS A-5759 – (Japanese Standards) Adhesive films for glazings

- USDA M0729 – Standards

- BOCA Section 723.2

- BOCA Section 723.3

- BOCA Section 803.2

- BOCA 1998 International Mechanical Code Section 604.3

ASTM B117 Salt Spray Tests (pdf – 40kb)

Northwest Testing Laboratories, Salt Spray Corrosion Tests.

ASTM C1363 (C236): Fiberglass Batt insulation comparison (pdf – 1.5mb)

Super Therm® tested by VTEC Laboratories. Super Therm® proved to be 240% better than fiberglass insulation. Super Therm® performs equally from -50 to 300F and is never affected by moisture.

Test results compared with other reflective coatings (pdf – 1.5mb)

Energy Star Program comparison testing shows very clearly that Super Therm® is the best coating on the market to maintain its reflective ability over 3 years with just 1% loss.

Sound Proof Test (pdf – 531kb)

Sound Testing performed by Hot-Cold Air and Fire Control by Pat Saulson, PhD. Sound reduced on average 50% for interior walls and 23% for exterior walls.

Resistance to Growth of Mould ASTMD-3273-82T (pdf 91kb)

Buckman Laboratories International, Technical Service Laboratory Report. Resistance to growth of mould in severe mould environments.

Fungal Growth or Soil and Dirt Accumulation ASTMD-3273

Buckman Laboratories International, Technical Service Laboratory Report, Table. Fungal growth or soil and dirt accumulation.

ASTM Tests (pdf – 58kb)

ASTM G53, ASTMD1653, ASTMD4060, ASTME96, ASTMD522, ASTMD412

- Visual effect of UV exposure – passed

- Water vapour permeability on organic coatings

- Abrasion resistance on organic coatings

- Water vapour transmission on materials

- Mandrel Bend test

- Tensile properties

BOCA Building Code Report (pdf – 91kb)

BOCA International Evaluation Report. US National Building Code 1999 – endorsement of Super Therm®.

Chicken House Test (pdf – 91kb)

Perimeter Industries Test Chicken House Roof – Cold storage facility for Jacks Hamburgers and Subway Foods, Cagle Foods.

Coke Pusher Cab (pdf – 251kb)

Sloss Industries Testing Documentation for Perimeter Industries, Coke Pusher Cabs Test, Stand Pipe Test, Steam Pipe Test, Oven Door Plug Test, Leveling Door Castings, Summary and Recommendations.

Ecopetrol Test (pdf – 80kb)

Ecopetrol Certification. Use of Super Therm® instead of Aluminium foil for insulation.

Emittance Test (pdf – 87kb)

Tennesse Tech Emittance Test.

Jet Engine Thruster Test (pdf – 250kb)

Jet Engine Reverse Thruster Test, (see graphs in pdf).

USDA Approval (pdf – 470kb)

Super Therm® is chemically acceptable as a coating for application to structural surfaces or surfaces where there is a possibility of incidental food contact in official establishments operating under the Federal meat and poultry products inspection program (pdf).

Purdue University: Emerging Construction Technologies

Super Therm® as an Energy Reducing Ceramic Cool Insulation Coating is Engineered to Block Solar Heat by deflecting, repelling and emitting thermal absorptance which reduces the solar heat being absorbed by 96.1% on an exterior application. As noted by a PhD in Fluid Mechanics, on exterior applications “SuperTherm® is deflecting better than 95% of the heat to begin with therefore debating the remaining 5% is trivial.”.

This was validated by the first certified thermal test conducted for Super Therm® being ASTM E1269 Standard Test Method for Determining Specific Heat Capacity by Differential Scanning Calorimetry in conjunction with ASTM E1461-92 Standard Test Method for Thermal Diffusivity of Solids by the Flash Method.

This was the certified ASTM testing recommended by the thermal laboratory located at Purdue University as it measures the thermal absorptance of the coating independent of the substrate to which it is applied.

This certified ASTM testing, documents the fact that Super Therm® reduced BTU’s absorbed from over 350+ BTU’s per hr\ft2\F on a bare metal substrate (Table 4) down to 4 BTU’s absorbed per hr\ft2\F on the metal substrate coated with Super Therm® (Table 5).

Purdue University Super Therm® Case Study

NOTE: Laboratory and Field project results as stated here may vary according to different climate conditions.