Trains and Railways

Trains, railways and railcars have many issues that the range of our specialised coatings are able to address. From solar heat block coatings on the roofs of stations to managing acoustics inside rail carriages. We’re also specialists when it comes to corrosion management of railway bridges and carriage frames with a range of international examples how our products help solve the toughest challenges.

- Railroad Rail Testing

- Tracks

- Bridges

- Locomotives

- Railcars/Carriages

- Sound proofing for Railcars

- Keihin Electric Express Railway Co. Japan with Super Therm®

Super Therm heat block coating cuts energy usage on Indian Railways Coaches

With the extreme heat in India, Super Therm® heat block coating has been successfully applied on coaches for Indian Northern Railway, Integral Coach Factory and Southern Railways, with an aim to deliver comfortable passengers experience and longer asset life. With one of the highest total solar reflectance of 96.1% solar heat block, it’s perfect for hot environments.

Northern Railway preference for Super Therm® application for their coaches was due to numerous reasons. The critical criteria were to reduce power consumption for running the air conditioning systems, enabling its effective performance for better passenger comfort. This is while running the trains in heat infested zones.

Other criteria were to have higher coaching stock availability through reduced maintenance. This is because of the fact that Super Therm® stops transfer of heat through the roof of the coaches by blocking 99.5% of the infrared ‘short wave’ from the sun. This results in blocking the heat load from the sun while preventing expansion and contraction of the roof surface caused by heat from radiation and altogether prevent corrosion due to condensation.

More information see RIT Coatings India or read the article (pdf).

Railroad Rail Testing

In hot climates dealing with rail and track buckling is a major issue and Super Therm proves it can reduce the heat load into tracks therefore reducing the actual tracks buckling which causes both safety issues from derailment but also time scheduling which can costs millions in lost revenues and save lives.

- Cooling of rail to avoid flex during summer months

- Eliminate derailment due to rail expansion

- Eliminate “stop run times” over rails due to expansion

Test

Reducing rail temperatures by Super Therm® ceramic coating on KCS/Watco rail systems.

Background

Reflective and white paints were tested in the 1980’s for reducing rail temperatures in hot sun conditions.

Temperature reductions were obtained, however, as the rail paint aged or became dirty the effects of these paints were reduced.

Working with Superior Products International II, Inc. of Kansas City, BLT Inc. realised that true ceramics in paint would allow many years of protection for maintaining reduced temperatures in hot ambient conditions. Reducing the buckling of jointed and long welded rails could now be accomplished.

On a hot day 30°C-40°C (90°F-105°F) typical and rail heats to 54°C-65°C (130°F-150°F). Most buckling occurs (3-6 P.M.) As the rail loads heat.

Test Site Location

Weldon to Heavener, OK. Mile Post 15-16 KCS

Rail

100 lb. RE (1912-1920) with mixture of tie plates (100-127).

Personnel at the Test Painting

(.25 mile painted north from hwy 28 rail crossing)

- 1. Ray Mathews – Watco Roadmaster

- 2. Paul T. Jones – Watco Consultant

- 3. Benjamin Ray – Paint application expert-Superior Products International II, Inc.-Kansas City.

Equipment

¾ Ton Pickup carried all the equipment. Additional equipment carried included a Power washer with 300 gallon tank of water for cleaning and a Graco G Max 2 gallon per minute Airless unit using a .031 tip size. Various steel brushes and cleaning tools were carried in case of need.

Procedure

Power washing the test section was unnecessary. This was determined by the fact that no rust could be wiped from the rail by hand.

On small amounts of vegetation, vines, etc. had to be removed to provide a clear painting area for the sprayer.

Painting of the 1/4 mile test rail started at 6:30 A.M. and was completed at 11:30 A.M. Ray Mathews felt this area would buckle as hotter temperatures occurred.

Paint was applied at 425 microns wet and 250 microns dry.

At 2:00 P.M. to 2:30 P.M. the ambient temperature was 34°C-35°C (94-96°F).

| Temp. deg. F | Temp. deg. C | ||

| Uncoated Rail | 126 | 52 | |

| Coated Rail | 105 | 40 | |

| Difference | 21°F | 12°C – 23% | |

| Uncoated Tie Plate | 136 | 57 | |

| Coated Tie Plate | 104 | 40 | |

| Difference | 32°F | 17°C – 30% |

This data points to the fact that the coated rail would probably never see 48°C (120°F) while the uncoated will go to 65°C (150°F).

Conclusions

The coating will keep the test site about 15°C / 30°F cooler and no buckling would be expected for the painted rail.

Tracks

RUST GRIP® the track base, pins and collars connecting the rails to the ties.

Apply RUST GRIP® on the support ties whether wood, concrete or plastic to strengthen and protect from oils, solvents, acids and weathering.

RUST GRIP® the bed over the rocks between the tracks to help stabilize and create a more secure and solid footing.

SUPER THERM® for cooling of the rail to avoid flex during summer months. Eliminate derailment due to rail expansion. Eliminate “stop run times” over rails due to expansion. See testing results below.

Bridges

RUST GRIP® over the entire structure of the bridge including all steel and concrete.

Bridges with existing Lead-based paints can be power washed with a 1500 psi power wash to remove only the dirt, debris and residues. RUST GRIP® has been tested and certified to encapsulate the existing coatings and secure the surface to a minimum of 6750 psi surface tensile strength. When applied over existing rusted surfaces or concrete, the RUST GRIP® penetrates into the pores and then locks down to secure the surfaces to prevent deterioration and stops continued corrosion. Using the RUST GRIP® eliminates the standard need for sandblasting which saves tremendous money and labor time when setting up for maintenance budgets.

ENAMO GRIP® can be used for a top coat to satisfy any colour schemes desired.

If areas are constantly wet or periodically submerged, MOIST METAT GRIP can be used to coat the metal and concrete to protect from weathering, water and chemicals.

Locomotives

RUST GRIP® to seal and secure the metal to prevent rusting. This is applied over clean surfaces without sandblasting.

SUPER THERM® applied over the cabs and in areas to prevent heat migration to the cabin and prevent heat build up in areas that need to be cool.

ENAMO GRIP® in colors or clear as a top coat and for graffiti protection and easy graffiti removal.

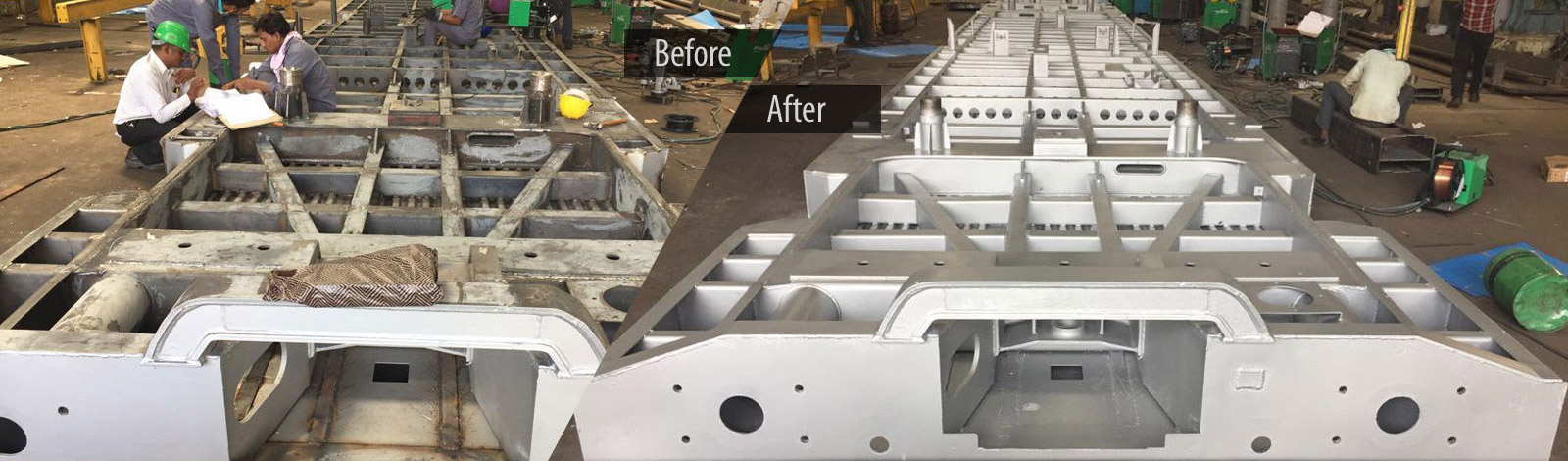

Rust Grip anti corrosive coating gives new life to Indian Railways coaches

Rust Grip, ‘One Part’ universal anti corrosive paint system gives a new life to LHB coaches at Sonipat Rail Coach refurbishment facility.

Rust Grip was selected by RCNK to have a longer asset life of the LHB coaches for the coach structure, precisely the under frames, bogie bolsters and the end walls.

”Rust Grip optimally does away with corrosion. Further, given its properties of one pack system it drastically curtails application costs and time. With the given, one pack characteristics, more numbers of coaches and wagons can be refurbished. This commensurately results higher the rolling stock out turn volumes as there are capacity constraints at most of the Indian Railway workshops given the very high work load at present”. Mentions Mr. Anil Kumar.

More information see RIT Coatings India or read the article (pdf).

Railcars/Carriages

RUST GRIP® to seal and encapsulate the exiting surface rust after initial cleaning. This prevents future rusting, extends the service life of the cars and saves on maintenance budgets.

SUPER THERM® the passenger cars, refrigerated cars for heat block prevention. Sun radiation and other heat sources cannot heat up the surface that is coated with SUPER THERM® It also offers sound acoustic benefits along with fire prevention.

ENAMO GRIP® over the RUST GRIP® and SUPER THERM® as a protective top coat and provides a gloss finish appearance.

LINING KOTE for the interior of chemical tank cars to protect from chemical corrosion.

HOT PIPE COATING on the exterior of refrigerated cars to insulate to help hold below ambient temperatures in and / or hot liquids in the tanks. Top coat with SUPER THERM® to seal and protect while finishing the insulation effect on the tanks. For a gloss finish coat, use the ENAMO GRIP® in the colour of choice on hot tanks and white finish for cold tanks.

The roofing of passenger cars coated with RUST GRIP® / SUPER THERM® and finished with ENAMO GRIP® to prevent rusting, help to cool the car and keep it clean.

Sound proofing for Railcars

Mike Collins, LTK Engineer, Los Angeles stated that Portland Streetcars had an issue with noise. SUPER THERM® was utilised to address the acoustics along with the additional benefit of fire, thermal and water proofing protection.

The noise problems on the streetcars is a problem with pure tones. The tones are generated in the motors at the IGBT switching frequency. There was something in the motors that is resonating. Moving the switching frequency +/- about the centre 2K frequency changes this noise.

As for road noise coming through the flooring, there is a remarkable difference between the Skoda cars with SUPER THERM® and the Tri-Met Siemens cars with the traditional batting. The difference is most noticeable in the low floor centre sections. The Skoda cars were much, much more quieter than the Siemens cars.

More about acoustic properties of 50-68% sound reduction with SUPER THERM®

Keihin Electric Express Railway Co. Japan with Super Therm

Source: Daiko, Japan

Application Date: September, 2003 Area: 3,200 sq m

Results

Comparison of temperature before and after the application of days with similar outside temperature. *The application was completed on September 5, 2003 (Measured time: 15:00)

| °C | Outside Temp | No 1 | No 2 | No 3 | No 4 |

| Before 4.8.2003 | 32.7 | 35.5 | 35.9 | 35.7 | 39.6 |

| After 10.9.2003 | 32.5 | 32.3 | 32.3 | 32.0 | 33.1 |

| Temperature Difference | -3.2 | -3.4 | -3.7 | -6.5 |