Commercial, Industrial and Manufacturing

To date thousands of m2 of roofing has been protected in Japan alone using Super Therm® for such companies as Canon, Hitachi, Kirin Brewery, Matsushita, Mitsubishi, Sony, Sumitomo to name a few.

Sony reduced kW by 86% with a 13 month payback

Sony Engineering group conducted field studies at the Koda factory and determined that the kW usage was reduced from:

- 3,764 kW in May 1994 to

- 519 kW in May 1995

- A reduction of 3,248 kW or 86%

- 5,647 kW in June 1994 to

- 1,869 kW in June 1995

- A reduction of 3,778 kW or 56%

This resulted in a payback of 13 months!

As a consequence Super Therm® was specified on their new 700,000 square foot facility in Malaysia.

Super Therm® was applied on a manufacturing facility in Kansas that was experiencing a great deal of difficulty in cooling various unconditioned buildings of the factory due to variance in size and significant volume. The results were an immediate reduction by 12°F on the lower levels, with an even greater reduction to the attic storage and overhead work zones on the second story. This temperature reduction enabled the facility to utilise simple ceiling fans for cooling during the summer months, and thereby lowering the overall expense of energy.

Reduce the solar heat, reduce energy in your warehouse during summer

Vodafone Mobile Phone Containers, Turkey

For transmitting the reception signal for mobile phones in Turkey, an air-conditioned container with electronic equipment is used. The problem is that the containers can overheat with extreme outside temperatures (30°C+) with the result that the equipment will malfunction or even break down.

One of the parameters is that the container had to have a constant inside temperature of 24°C that could often not be reached with the air conditioner that was used.

The problem is that there are significant electricity costs for cooling the container to the right, constant temperature of 23°C. The containers are 2 x 2 x 3 meters, which are 24m2 for the entire container, bottom excluded.

Treat the container with Super Therm® on the outside to reflect the direct sunlight, so that the air-conditioner can reach the inside temperature of 23°C more easily and that eventually energy savings will occur.

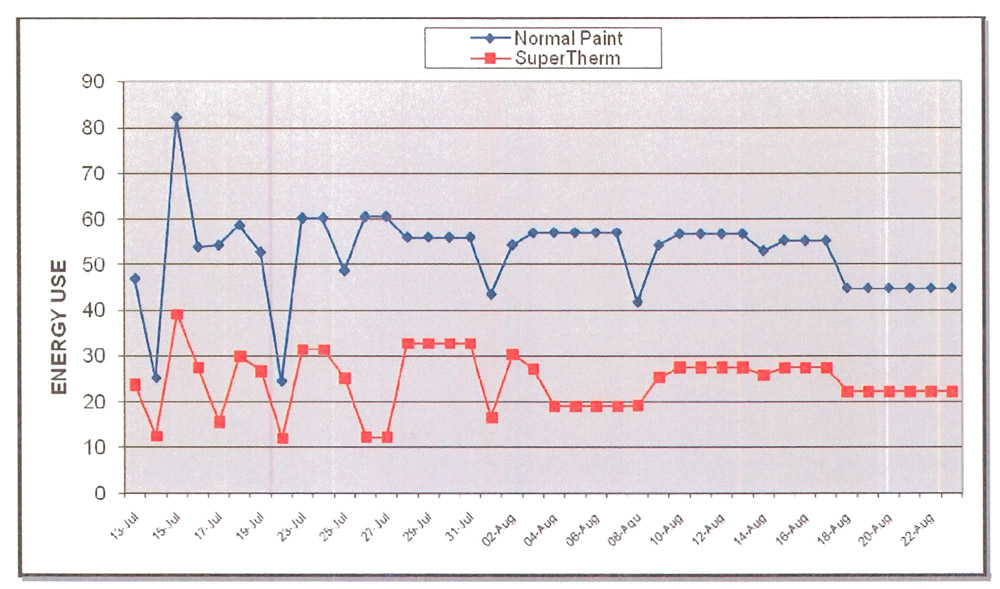

Conclusions: Inside temperature of 23°C was reached. This allowed for reduction in energy consumption. See the report >