‘Insulating’ Paint Merchants Dupe Gullible Homeowners

We addressed this article that is reproduced on Wikipedia. Again, the lack of facts related to the testing means that people are reproducing links and references as if it’s the truth…it’s not when it comes to the real Super Therm®. You may notice the editor of this article is Martin Holladay, he’s got another article ‘An ‘Insulating’ Paint Salesman Is Tripped Up By His Own Product‘ Martin acknowledges “Since January 2002, when I was hired as editor of Energy Design Update, I have worked full time researching and reporting on energy issues. That is what I have “personally done.” So no testing with the real Super Therm® but plenty of opinions about it. You’ll discover that Martin’s references to the reports are so far out of place that one report actually uses the wrong fake Supertherm paint product in the cold Alaska landscape and the other refers to a 1991-1994 Florida testing that actually shows significant positive results by the very organisation which has endorsed the real Super Therm® not that our coating was used in the testing.

Articles like these perpetuate mistruths about the real Super Therm® and we just rip it apart! This is another case of Cognitive Dissonance. When people hold very strong beliefs and they are presented with evidence that works against that belief, the new evidence cannot be accepted. Therefore they look for evidence to prove their belief even though the facts are in plain sight. Martin should check his facts much closer! Full manufacturer responses at the end of the article!

As con artists profit from ‘insulating’ paint, the FTC is MIA

Green Building Advisor

By Martin Holladay | September 11, 2009

https://www.greenbuildingadvisor.com/article/insulating-paint-merchants-dupe-gullible-homeowners

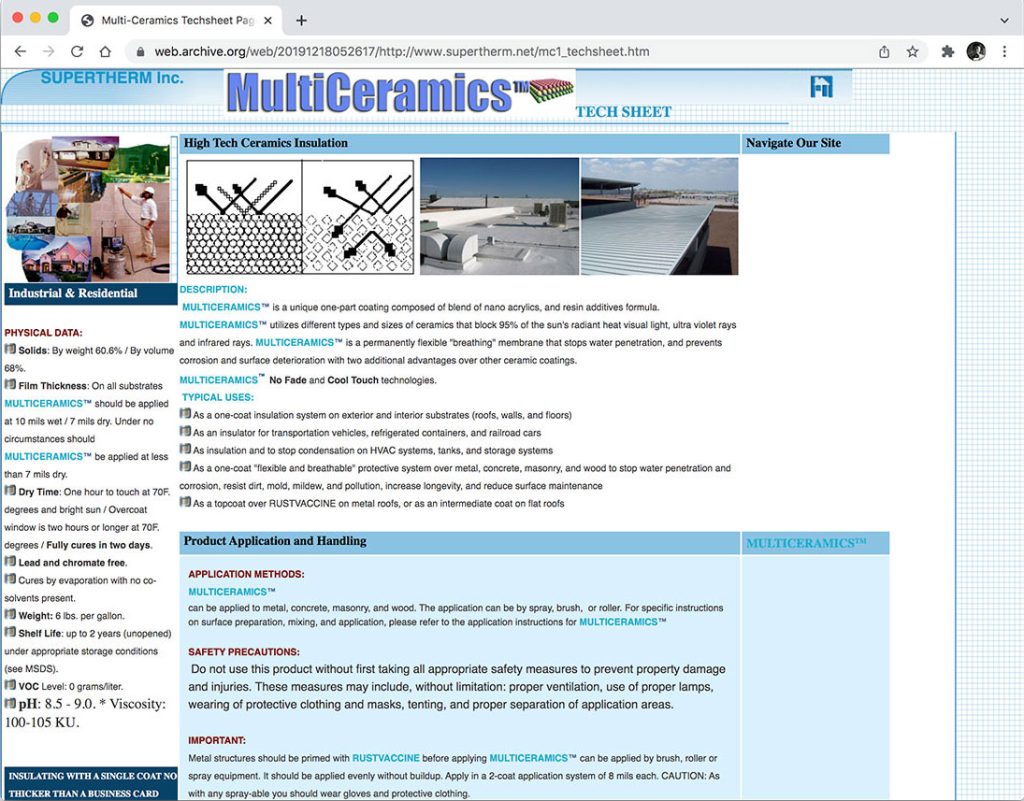

Scammers have been selling “insulating” paint to gullible consumers for at least 27 years. Among the exaggerated claims made by distributors of these overpriced cans of paint is that the “low-e” coatings will “lower energy bills.” In addition to liquid paint, some fraudsters sell powders or paint additives, usually described as “miracle” products containing “micro-spheres” or “ceramic beads.”

We agree that there are many fraudulent products that mislead consumers in the marketplace. Good quality companies and products can get caught up in the misrepresentations and are working to establish their integrity and credibility. Other old industries are also driving complaints as new technology impacts their business growth. Regrettably as the Governments fail to establish clear regulations and standards there will be ongoing issues.

Every few years, the sleepy regulators at the Federal Trade Commission (FTC) wake up long enough to send warning letters to the most egregious paint scammers. For example, in 2002 the FTC clamped down on Kryton Coatings International, a manufacturer which claimed that its paint was equivalent to 7 in. of fiberglass insulation. In March 2009, the FTC took action against Sumpolec, a marketer of coatings that were said to “equal R-100 insulating value.”

We understanding what it’s like to have our product and brand misrepresented. It is important to establish the difference between the real Super Therm® originally invented and manufactured by Superior Products International II. Inc. in Kansas and a company called Supertherm Inc. in Arizona, USA. Supertherm Inc. is also being investigated by the FTC which set up a business name similar to the creditable coating of the real Super Therm, however it is not a credible coating. This has caused untold damage and confusion to the real Super Therm®.

To find them, just lift a few rocks

In spite of these rare actions, however, marketers of “insulating” paint continue to thrive. With a simple Google search, any Web surfer can conjure up dozens of distributors of insulating paint, including those hawking Nansulate and Super Therm.

Again this isn’t accurate. While we can’t speak for Nansulate, The real Super Therm® has been tested by independent labs in Japan, Russia and the USA. This includes 3 separate tests by the Florida Energy Office in the USA in three different locations and methods with the same proven results. Not to mention the hundreds of field and industry studies and results. The real Super Therm® delivers on its proven statements.

When I was the editor of Energy Design Update (EDU) — a position I held before joining the GBA team in November 2007 — I regularly exposed exaggerated energy claims made by paint manufacturers. My March 2004 article, “R-Value Scofflaws,” fingered the manufacturer of Super Therm. In June 2008, I wrote “Scam and Exaggeration Roundup,” an article highlighting exaggerations made by Nansulate. Although both articles were forwarded to the FTC, the agency has so far failed to act against either manufacturer.

While Martin Holladay crudely makes a statement above we’re unable to find or identify the “R-Value Scofflows” or the “Scan and Exaggeration Roundup” articles that he claims he’s written, He did write another article ‘An ‘Insulating’ Paint Salesman Is Tripped Up By His Own Product’ which we debunk. Martin makes a comment in his responses for GBA “Since January 2002, when I was hired as editor of Energy Design Update, I have worked full time researching and reporting on energy issues. That is what I have “personally done.” So firstly he’s an editor and has never tested the real Super Therm yet has plenty of opinions about it all from wrong reports or articles and has never contacted the manufacturer for a balanced view as most ‘editors’ would do, sounds like its more about getting page clicks on articles rather than balanced reporting.

“A barrier to heat transfer”

The manufacturer of Nansulate — Industrial Nanotech of Naples, Florida —describes its flagship coating as a “liquid applied home insulation.” The company’s Web site (sic dead link) falsely claims that “Nansulate is a new technology which insulates by means of low thermal conduction. … Residential customers typically report energy savings in the 20% to 40% range, which is of course dependent on each individual application. … You can boost the energy efficiency of your home by applying Nansulate to the interior walls, ceiling, and attic area. Nansulate will act as a barrier to all three methods of heat transfer — convective, conductive, and radiant. Radiant heat transfer is one of the most significant ways that heat is lost or gained from a home or building. Nansulate can be used as attic insulation, pipe insulation, wall insulation, and duct insulation in your home, helping you lower fuel bills.”

This has nothing to do with the real Super Therm.

“R-19 equivalent insulator!”

If anything, the claims made for Super Therm are even more outlandish than those made for Nansulate. One Super Therm distributor, Eagle Specialized Coatings of Surrey, British Columbia, advertises that “Super Therm is a true ‘insulating’ coating and not just a reflective paint as are all the competing formulas in the market. Also tested by the Thermophysical Research Laboratory for comparative R-19 equivalent insulation factor Super Therm blocked 92% of the heat. No other R-19 equivalent insulator can claim that! No Fiberglass, No Foam, No Cellulose, No other single ceramic paint!”

Prior to understanding coatings and making claims, there were no standards for coatings so all you could do was state ‘Equivalent’. The real Super Therm® was tested in a lab to be equivalent with regard to blocking heat. We no longer make this statement as coatings and paints are unable to ‘resist’ heat like bulk insulation, therefore R and RE-values have no meaning to us. We now focus on total heat transfer – U-values. Here is the lab report on Super Therm by the Thermophysical Research Laboratory that showed Super Therm temperatures were tested at 23°C, 50°C, 75°C and 100°C. Super Therm blocked the BTU heat load from 367 down to just 3.99 BTU at 100°C. The metal surface not coated allowed 367.20 (108 watts) to enter a storage tank per m2 per hour. Metal coated with one coat of Super Therm® allowed only 3.99 BTU (1 watt) to enter per m2 per hour. Japanese testing showed Super Therm blocked Short Wave block – 92.2% (Visual light heat). and Russian testing showed Super Therm blocked Short Wave block – 95% Avg (Visual light heat).

NOTE: Laboratory and Field project results as stated here may vary according to different climate conditions.

The manufacturer of Super Therm, Superior Products International of Shawnee, Kansas, claims that “Super Therm is a ceramic based, water-borne, insulating coating, designed to block heat load, moisture penetration, and air infiltration over a surface and to reduce energy costs. … Super Therm can provide energy savings of 20-70%. According to use and application. R-19 Equivalent Rating — Super Therm reflects over 95% of radiation from the sun replacing the 6 to 8 inches of traditional insulation to block initial heat load.”

Yes it was true. We have both FEO (20-50%) and industry testing that validates these energy savings claims. Unless of course people want to argue as well with the the Florida Energy Office and NASA. RE-values no longer apply as explained previous.

How can these paint manufacturers get away with such wild exaggerations? Although the problem is due in part to the FTC’s lax enforcement of existing regulations, other factors play a role. According to an article in the September 2009 issue of EDU, “Such claims, as a rule, receive relatively little attention from energy experts. That’s partly because they are numerous enough that any attempt to debunk them individually would quickly develop into an open-ended game of Whack-a-Mole, and partly because the product claims are so outlandish that it’s difficult to imagine anyone taking them seriously.”

Super Therm® was developed in 1989 and make statements we can substantiate. We have so much testing we make public unlike other companies. The real Super Therm® has been tested, check and validated. NASA, Florida Energy Office and three independent Laboratories in Japan, Russia and USA can’t be wrong about the real Super Therm®.

The same as ordinary paint

Every researcher who has examined these products has concluded that there is no such thing as insulating paint. For example, tests at the Florida Solar Energy Center confirm that these paints are nothing special: “The Florida Solar Energy Center has tested ceramic paints and found them to have no significant advantage over ordinary paint in terms of their ability to retard heat gains through exterior building surfaces.”

So when it’s stated ‘these paints’ where are the test results, names of the products tested or any information there’s nothing to show? Just a statement on a website with no evidence of testing. We link and prove all our independent testing results. Again, these articles link to bold, unsubstantiated statements with zero testing results as evidence. The evidence to the testing we did find showed the testing was from 1991-1994. That’s over 35 years ago. Really?

The report did say however “A highly instrumented test building in Oak Ridge, Tennessee showed that reflective coatings reduced the peak heat flux on the underside of the roof decking by up to 82 W/m2 relative to a black colored EPDM roof section [12]. This represented a reduction in overall roof-related cooling load of 75%. In a 465 square meter structure without roof insulation this would represent a reduction in the building thermal load of 10.8 tons (38 kWt) of air conditioning.” and “Summertime air conditioning was reduced by 21.9% in the building with the reflective roof coating.” Interesting our friend Martin Holladay didn’t state that fact! “It was recognized that the test house likely understated the average savings of a reflective roof system in existing Florida homes.”…“Peak demand savings average 30%” and there’s more. So the statement of “have no significant advantage over ordinary paint” is absolutely incorrect from their own report. Blatant incorrect facts!

Interesting the Florida Energy Office did a test with the real Super Therm in July 2003 and stated “As installed, at the time of this survey, the SuperTherm Roof Coating System proved to be an effective Energy Conservation Measure (ECM) that produced a reasonable simple pay back of approximately 2.2 years on this particular project. This would indicate that it’s application could be fundable with Federal and / or State of Florida Energy Grant Dollars where applicable. On behalf of The State of Florida Energy Office and the United States Environmental Protection Agency, let me thank you for your efforts in developing an affordable product that obviously can be instrumental in Conserving Energy. We hope you will continue to consider Florida as a valuable market for your products.” Their results showed Standard Roof load with no insulation coating: 226,000 BTU’s per hour, Super Therm Roof load: 93,500 BTU’s per hour = 59% energy saving! The Florida Solar Energy Centre didn’t test the real Super Therm and haven’t stated what they did test with.

NOTE: Laboratory and Field project results as stated here may vary according to different climate conditions.

The latest research lab to shine light on the insulating paint scammers is the Cold Climate Housing Research Center (CCHRC) in Fairbanks, Alaska. As explained in the September 2009 issue of EDU, CCHRC researchers decided to focus on two products that often generate customer complaints: Nansulate and Super Therm.

Firstly we’ve never received performance complaints about the real Super Therm®. Supertherm Inc. (see above is not the real Super Therm) is a paint and customers would complain about that, it was tested with Nansulate (no longer exists) another paint. The 2009 testing by the CCHRC never contacted Superior Products International II. Inc. the manufacture of the real Super Therm® and therefore the CCHRC have tested the wrong product and this misrepresents our quality brand name and trademark. The CCHRC has used the wrong product and then utilised the information from the real Super Therm® in its testing report. This is a fundamental mistake by the CCHRC as the real Super Therm® was not actually included in the testing.

In fact the President of Superior Products International II, Inc. and inventor of Super Therm®, J.E. Pritchett made a lengthy response to the article or read below this article.

Are they low-e?

In theory, the lower the emittance (emissivity) achieved by a paint, the better its performance. When CCHRC researchers tested the emittance of dried samples of Nansulate and Super Therm, however, they discovered that neither coating is low-e. An independent laboratory “tested the emittance of the coatings on three different samples for each coating. Super Therm had an average emittance of 0.9 and Nansulate had an average emittance of 0.92, which demonstrates that neither product is a good inhibitor of infrared radiant heat loss.”

Low-e works only if you’re trying to keep heat contained. The real Super Therm has high emissivity so the conductive heat is released through the coating back into the environment. So on one hand Martin is quoting the Florida Solar Energy Center running testing in 1991-1994 on solar heat block paints which did show a net positive result for reflectivity and energy savings, then bundling in the CCHRC report and talking about low-e coatings in cold environments of Alaska. That’s definitely mixing your apples with pumpkin…not even the same universe of comparison. These article are bogus to discredit any real and proven new technology that does work.

The measured emittance values of these paints are truly dismal — far higher than the legal maximum for a radiant barrier, which is 0.10. (As it turns out, no paint on the market can meet the radiant barrier standard.) Some paint manufacturers classify their products as “radiation control coatings,” a category requiring an emissivity rating of 0.25 or less — a less stringent emissivity rating than radiant barriers. However, neither Nansulate nor Super Therm comes anywhere close to even this less stringent standard.

Actually the emissivity values are good depending on your objective. We have other coatings such as HSC which contains heat…perhaps the CCHRC could have tested that…naturally contacted Superior Products International first.

In any case, the emittance of residential paint is a moot point. A low-e coating is only effective if there is a large temperature difference between the surface being coated and the environment it faces. Such a large temperature difference can only occur on an uninsulated wall — and if your house has uninsulated walls, you have far more problems than can be solved by a few cans of paint.

Blah blah comment. Super Therm is a specialised solar heat block coating that acts as a thermal barrier that dries to 250 microns so you’ll find ‘paint’ is approximately 100 microns max. We really don’t see the point of this article mixing up hot environments of Florida with Alaska…we notice Martin didn’t make that very evident and leaves the reader to join the dots.

Can paint have an R-Value?

In order to leave no stone unturned, the Alaska researchers measured the R-value of dried paint samples. Employing a Fox 314 heat flow meter, the researchers followed the standard ASTM C518 procedure for measuring R-value. (For more information on the ASTM C518 test, see “Understanding R-Value.”) Since a thin coat of dried paint is fragile, the paint was applied to 1/2-in. drywall before testing.

Pointless because the Alaska researchers were testing paint and not the real Super Therm®. Why didn’t they contact the manufacturers first? So they’ve tested the wrong product, published the results, which are wrong and then all the follows like Martin believe the report and share misinformation…a wrong fact becomes the truth if enough people stupidly believe it. Maybe the CCHRC could rerun the testing and work with the manufacturer and share an accurate report.

The results will undoubtedly disappoint the marketers of “insulating” paint. “Application of Super Therm increased the thermal conductivity of the gypsum board and therefore decreased the overall R-value,” the researchers reported. “Application of Nansulate resulted in no significant difference, as the change in thermal conductivity for the Nansulate-coated gypsum board is within the 1% measurement error of the Fox 314.”

Important to note its Supertherm Inc. not the real Super Therm®. No we’re not disappointed in our coating…it’s amazing. We’re disappointed in this bogus article and many more like them that don’t clarify all the facts and just regurgitate the same stuff in an internet circle.

If a tree falls in the forest …

Of course, R-value results are often ridiculed by those selling “alternative” insulation products. As Jon Vara, the current editor of EDU, recently explained, “Manufacturers of insulating paints typically claim that, although their performance can’t be quantified by some standardized tests, they are effective in the real world. A possible explanation: they only insulate when no one is looking.”

No our claims of the real Super Therm® are through standardized tests.

In order to test this unlikely possibility, the Alaska researchers built three insulated test boxes lined with drywall. The drywall in the control box was painted with ordinary latex paint, while the two test boxes were painted with Nansulate and Super Therm. “The boxes were placed outside and the heaters operated overnight maintaining the inside temperature at an average of 74°F,” the researchers reported. “Data were not collected during the day to avoid interference from solar heat gain. This control testing was conducted over the course of a week to ascertain that the boxes required the same amount of energy to maintain temperature. … Following the painting, all three boxes were set up with the sensors and heaters just as they were in the control tests, and tested outside overnight once every two weeks for a 30-day period.”

Again, not the real Super Therm®, this is a pointless article as the basis of the testing is incorrect.

“No discernible difference”

No discernible difference in the other rubbish articles about the real Super Therm® we agree.

Guess what — paint is a lousy insulator. The CCHRC researchers concluded that “there was no discernible difference in the performance of the Super Therm or Nansulate in comparison to regular latex paint during the energy monitoring tests.”

Yeah the CCHRC did compare paint with paint and didn’t get it correct from the start!

The ball is now in the FTC’s court. Anyone who wants to give the FTC a nudge should contact Hampton Newsome, the FTC attorney who handles enforcement of the R-Value Rule. Newsome can be reached by phone at 202-326-2889; his e-mail address is hnewsome@ftc.gov.

The full CCHRC research report, “Product Test: Nansulate and Super Therm,” was available online (we have a copy here).

Firstly the CCHRC don’t have any references to the fake Super Therm or Nansulate on their website or the report…maybe because it’s incorrect? So we’ve helped you and put it on our website.

Notice the reference to the Florida Solar Energy Centre report “Measured Cooling Energy Savings From Reflective Roofing Systems In Florida: Field And Laboratory Research Results” is missing. Reference Publication: Parker, D., Barkaszi, S., Chandra, S., Beal, D., “Measured Cooling Energy Savings From Reflective Roofing Systems In Florida: Field And Laboratory Research Results,” Funded by the Florida Energy Office in support of the Building Design Assistance Center. Disclaimer: The views and opinions expressed in this article are solely those of the authors and are not intended to represent the views and opinions of the Florida Solar Energy Center.

Okay so the Florida Energy Office funded the report that the Florida Solar Energy Center has republished with their own opinion and Martin Holladay has just posted as ‘evidence’ from a 1991-1994 report. This is the same Florida Energy Office that thanked the real Super Therm. “On behalf of The State of Florida Energy Office and the United States Environmental Protection Agency, let me thank you for your efforts in developing an affordable product that obviously can be instrumental in Conserving Energy. We hope you will continue to consider Florida as a valuable market for your products.” Alaska’s not really our market. The real Super Therm® loves the heat!

Boom…mic drop Martin!

Please read the positive responses below. You’ll find Martin and other merry bandwagon of negative comments have no experience with the real Super Therm apart from their opinion and their backyard testing. Enjoy!

More Debunked Media

Responses

We have not covered all the negative arguments of Martin Holladay. This is his response to a post in the threat regarding his experience on solar heat block coatings and Super Therm on Oct 06, 2010 to Randy, AKA Texas Builder “Since January 2002, when I was hired as editor of Energy Design Update, I have worked full time researching and reporting on energy issues. That is what I have “personally done.” So no testing with Super Therm but plenty of opinions about it.

J.E. Pritchett | Sep 14, 2009

When the manufacturer of SUPER THERM found out about the testing in Alaska, the office called the testing group to find out what was the purpose, the procedure, the authorization and the qualification to do the test. The manufacturer has ceramic products but states very plainly in their literature that SUPER THERM is a reflector of the radiation waves given from the sun. If someone needs to insulate in cold climates, they must use their other ceramic coatings designed specifically for this type of insulation requirement. The lab that did the testing did not contact the manufacturer to find out which product was best for what they were testing for. They chose to do testing on a product that was not qualified by the manufacturer to perform in this application. The ceramic coating designed for cold climates have been tested and have W/mK heat transfer numbers to qualify them for such uses. The lab said they got the product from someone?? who said it would work but the lab never did their due diligence to call the manufacturer to make sure they had the correct product. As we see, it is easy to criticize new technology and especially when there have been mispresentations in the market by many of the “reflective paint sellers”. Those who have spend years testing and finding the combinations of ceramic compounds that can provide insulation effect don’t need nor deserve this type of press just because it is easy to throw them into the same room with “reflective paints”. As to testing or lack of testing referred by Mr. Holladay in this article, he has never seen nor brothered to review all the testing performed by ASTM laboratories on SUPER THERM and the other ceramic coatings marketed by Superior Products International. The Florida Energy Office Specialist in Tampa Florida did three tests on SUPER THERM in three separate parts of the US (Florida, Colorado and Texas) to determine if the product performed as stated, and it did. Bombardier Engineering did the most extensive insulation test (ASTM C 236) on a fiberglass board and then SUPER THERM to find SUPER THERM outperformed the fiberglass by as much as 148% improvement. Superior Products International has all the testing to prove the 20%-70% savings in testing and field studies covering over 100,000,000 sq.ft. of roofing in the books for review. I cannot speak for any of the other reflective or “insulation” coatings in the market, but I can definitely speak on the behalf of SUPER THERM and the other ceramic products in its’ line and the company will not report facts and figures unless it can prove them, and it can. The products were developed while working in the oil fields and under the eyes of engineers which is why all the testing is at hand for review. The product line was not developed for home owners, even though they will work on homes, of course. The products were developed for the worst situations in petrochemical plants and work. To bring them into homes is not a stretch. The entire point is this: The products perform as the manufacture reports and can prove it. Taking a sample of one of the products to an Alaskan test lab that choose the wrong product for their climate is a failing of the lab and not the product. For Mr. Holladay to choose SUPER THERM for these unfounded accusations shows a total lack of research on his part. I do have a very legitimate question for him. Has he ever really checked the testing performed on fiberglass or the other “thick” materials to see how they are tested for their “R” rating, lack of humidity, specific single temperature point to represent all climates?? Did Mr. Holladay ever stop and question in his own house if he had an R 19 insulation using batt insulation, when in fact his studs are 2X4″ allowing only 3″ of batt and not the 6″ that is the rated R19?? Acceptance of “status quo” allows only to criticize new developments while living in the Mother of all misconceptions. I would love to see him reserach the status quo insulation products and report his findings. We have, and would love to compare findings. This is a level playing field, and we would respectfully request we all play on it.

J.E. Pritchett | Sep 14, 2009

I did forget to agree with anyone arguing that coatings do not have R values. The R value was designed for and by the fiberglass industry in the 70’s to explain and sell the product. This is why an inch thickness must be in the formula mix. Coatings are not applied in inches and therefore cannot have “R” values. Unfortunately, because people have their heads wrapped around only the “R” value as a point of reference, the coating companies try to explain their effectiveness by using the R equivalant relationship which is perfectly acceptable in a comparison sense. Retailers do this every day and the FTC is fine with it. As to the FTC, they do require an ASTM test procedure as part of the requirements to qualify an insulation coating to show it does perform the heat blocking ability, and it is the ASTM C 236, which SUPER THERM has performed.

Blocking “heat load” is the key to controlling the amount of heat “avialable” for transfer. Either from sunlight (summer) radiation heat loads or convective heating (winter) interior loads to transfer to the cold exterior. If a wall or roof member can be coated to help block the loading of the heat, then the load and transfer is reduced and therefore offering the insulation effect most needed. When thick materials are designed to absorb heat and slowly transfer it (therefore the R value which is the measurement of how fast this will happen), this means you will lose and gain heat at a constant rate, and it increases with moisture and air flows in the walls and roofing (no typical construction is air tight). If the walls are sealed to help prevent the loading of moisture and reducing the air flow, physics tales over since a dry substrate is a better insulator than a wet one with a tighter air flow allowed. SUPER THERM is a tested “water barrier” to a 55 mph wind driven rain. It has a permability of 8.8 which allow it to breathe but helps to block wind flow. In summer, 40% of the A/C cost is dehumification, according to the Energy Specialist. Also, when the coating is applied over a wall, it is fully covered. Batt insulations only are installed between the studs which are ever 16″. An infrared picture taken of a home in winter shows all the studs and joinst exposed in orange and yellow revealing the lost of heat every 16″. This is covered by SUPER THERM and helps to prevent the lost or gain of heat in this “every 16” pattern.

There is more to insulation than the “R” rating and in the 21st century, the technologies are finding it.

J.E. Pritchett | Sep 15, 2009

The rebuttal from Mr. Holladay

1. He is correct, a lab can test any product they chose without authorization. Problem is, would you think the lab would want to test a correct product to match up what they wanted to know. If it is for cold or for radiation which requires two different products. One product cannot do everything and this is simply a fact. So the lab tested a heat radiation product in a cold climate without sealing the exterior walls as we suggested when using this product. What does the result mean?? nothing.

2. All this information is correct. Records and studies are in the files showing the complete range of savings using SUPER THERM.

3. It is not a lab and never was. It is the South Flroida Energy Office and the specialist worked out of this office to travel and do their testings.

4. I never said Bombardier was a testing lab. They are an engineering group that is known worldwide. They had the SUPER THERM tested under the ASTM C236 to find out if it performed as marketed, and it proved it did. A compbination of labs were used to do this single test using VTEC labs to International Labs in Pa. to build the panels and set up the testing. Bombardier did the testing to find a replacement for fiberglass in their train cars. I am surprised he does not know who Bombardier is.

5. It was tested at Purdue, the testing was reported and the facts stand as they are. Comments such as “false claims” is words thrown against the wall to see if anything sticks. As I said, we started in the petrochemical field and only recently have looked at homes in our marketing. Again, total lack of knowledge on this subject shows.

6. If this is the case, then he agrees that compacting fiberglass does not reduce its’ “R” rating. This is totally false. For a “R” 19, it must be 6″ thick. If you compact it down to 3″, you have reduced it down to R 9.5. This is physics and the way it is measured. So why has this never been questioned as to all the homes with 2″X4″ construction and the code to be R19. As said, status quo is a comfortable seat.

7. The ceramic compounds are low density and will not absorb and load heat— this is physics. A metal plate has high density and will absorb and hold heat. A piece of paper has low density and cannot absorb and hold heat like the metal. If the low density ceramics have a lower density than the paper, they do not absorb and hold heat, therefore repelling the heat off the surface which is why the emissivity of .92 is correct. If Mr. Holladay thinks this is all incorrect, then he needs to take on the entire Cool Roof Rating Council (CRRC) and Energy Star which claims the high emissivity as repelling heat.

8. I do agree with Mr. Holladay that this case is closed. To continue this conversation is at this point worthless due to the lack of knowledge and throwing half truths against a wall. For the readers and ourselves, it is a soap opera at this point of which no one is interested.

Texas Builder | Oct 04, 2010

Oh my! Where to begin?

It would be impossible to begin contradicting every incorrect point made here. Far too many wrong statements have been made to attempt that.

So many words spoken, so much time and effort spent, by people who have no idea what they are talking about.

Honestly. “Testing” a heat reflective coating…..in snow??? Where’s the heat source?

Pure idiocy.

What I can tell you is that I have personally tested many of the products on the market before incorporating them into my business. I found many to have no value whatsoever and the sellers of these products to be very defensive when pressed. What I also found, was one that worked. Worked incredibly well actually. I’m sure that not many would argue that with any product there are good and bad instances. Why wouldn’t that be the case with these types of products?

While I appreciate the time and effort put into this by some, I cannot understand how they can move forward doing so when they have no idea of the basic concepts beforehand. Understand how something is supposed to work THEN come up with a way to test it. Whatever happened to the “scientific method” we are taught as children in science fairs? We don’t consider that, but we’ll believe some yahoo that becomes some kind of backyard scientist or armchair researcher. Ridiculous.

For anyone who has a desire to educate themselves I invite, even challenge you, to contact either myself or the staff at Hy-Tech Thermal Solutions. The manager there, Tony, was extremely patient and helpful with me when I too was in the learning stages.

Some products work. People just need to get their head out of the sand to find them.

Texas Builder | Oct 05, 2010

Response to Martin

Yes I said that your article contains may incorrect points. Please don’t take my unwillingness to spend an hour and 5000 words as being “unable” to correct you. What I was trying to say is that there is SO much misinformation, it would be difficult to know where to begin.

But I’ll start with this. Why don’t you tell us all how much personal research and interaction you have had with any product in this category? That would be a great place to begin establishing your credibility on the topic. Have you used any of them? Have you tested any of them, incorporating the scientific method that is largely accepted?

Or are you just another person with a keyboard and internet access who attempts to achieve some kind of credibility by regurgitating “information” you find out there on the web and blindly follow?

Now as for my information, it is gained by direct testing. Spending my own money and using these products on my own property and in controlled experiments. Experiments that make sense once one has a grasp of how the products are supposed to work. Testing is Alaska is as ridiculous as testing a car under water. Laughable…if it wasn’t so sad.

I tested 8 products. I found 6 to be worthless (and it is there that I agree with you), 1 to give absolutely minor results, and 1 to be quite substantial. It was then that I contacted all of the manufacturers and asked the hard questions. The responses matched the products. Mostly of no value with one exception.

The other test you speak of…have you read them? Each and every word? I have. I’ve also read, and spoken to, a great many people other than that.

Let me ask you this. Is it possible, even remotely, that there can be a category of products where some work and some don’t?

Is it possible that some of these “testing” agencies did not test all products in a category, but just one or two at best? That’s not a fair question because I already know the answer. I know because I contacted them.

My point is this. While I greatly appreciate and admire what you do to educate the public, there is a great responsibility that goes along with that. The responsibility of educating oneself fully. That is my belief before introducing anything to my customers, and I take it quite seriously.

If you want to use words like “dupe” and “con artists” I’m right there with you regarding some of the products out there, and I’ll be your biggest supporter.

But to lump every product out there into the same category by using nothing other than a cursory understanding (at best) and other information you find on the internet…..well that’s just simply irresponsible “journalism”.

Texas Builder | Oct 06, 2010

I defer to you then, Mr. H

I agree completely with the need for standardized testing.

Would you please enlighten us with the ASTM test for the reflection of heat?

(and we’re talking about heat here…not solar reflection)

I can save you some time. There is none.

The problem is that far too many people love to throw names around like ASTM, Energy Star, and a host of others….yet have put in ZERO time to actually research what they do or where they may be lacking.

The point that I was trying make, that you very artfully dodged, was that I have invested time and money into researching products in this category. I know about them, and I know about these agencies who claim to be concerned with the advancement of technology and saving the planet…yet do very little other than collect money.

Again, it does no good to make points when you clearly are unable to address them. If only your research skills matched that of your ability to evade. Your mind is already made up, and obviously closed to any reasonable thought on this topic.

You do a very good thing by providing information to the masses.

All I’m saying is that you should stick to writing about things you actually know something about.

That’s not too much to ask. Good for the public…good for your credibility.

Martin Hollaway | Oct 06, 2010

ASTM test procedures

Texas,

If “insulating” paint actually slows down heat transfer, then the effect of the paint would be easy to measure using standard test procedures for measuring heat flow. These test procedures include:

ASTM C168, “Standard Terminology Relating to Thermal Insulating Materials,”

ASTM C518, “Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus,” and

ASTM C236, “Standard Test Method for Steady-State Thermal Performance of Building Assemblies by Means of a Guarded Hot Box.”

Texas Builder | Oct 06, 2010

Well done, Mr. H

A very fine example of internet searching.

I do, however, have to ask this. Have you actually spent the 39 dollars per each test and actually read each and every word? I know I have.

My point is that had you actually read them, and had more than a cursory understanding of how ceramic spheres work, you would be more than able to determine the flaws in the test and how they simply do not apply to new technology. What is the date that these procedures were adapted? What changes have been made over the years to adjust to new advancements?

Do you know the answers to these questions? I think we both know the answer.

I, however, do know this. Because I have done my research.

It seems, as I said before, that some of these agencies are more interested in generating revenue than actually doing anything positive.

The question that remains unanswered, is what have YOU personally done to research this topic?

A very simple question that has great value.

Answer that…..and you may begin to have the credibility you should have on something you write about.

All the best to you.

Randy

buildingtexas@yahoo.com

Response to Randy

Randy,

Since January 2002, when I was hired as editor of Energy Design Update, I have worked full time researching and reporting on energy issues. That is what I have “personally done.”

In spite of my repeated requests, however, you have still not provided a shred of data.

I think we’ve just about wrapped up this dialog.

Building Texas | Oct 07, 2010

Again we agree, Mr. H

This is pretty much wrapped up….as you’ve now made it clear that you have ZERO personal knowledge and experience with products of this type. Also no understanding of how they work, otherwise you would know that a test in Alaska is ridiculous. You would have bypassed it as the hogwash it is…instead of posting it as some type of meaningful exercise. Just fodder for another “article”.

Even if I did take my valuable time to post all of my research, the control method, documentation, everything……something tells me that you would immediately dismiss it. Something easy to say like how it’s not done at a “lab” or some such nonsense.

I researched, tested, then painted a particular product in my attic. Paint.

My attic temperature dropped 25 degrees. A house I painted in Texas? Mid summer electric bill is $98 for a 2000 square foot home.

I know for a fact it works. I’m just trying to correct bad information that’s floating around on the web and inform consumers.

What I’ve asked you to do is two-fold. State your personal experience with products you write about, and enter into a dialog about products in this category that DO work. You have shown no interest and failed miserably on both counts.

While I envy you in that it’s a wonderful opportunity to get paid to write about things you know nothing about…..the disservice you do to the public is abhorrent and irresponsible.

You may now put your blinders back in place and go on about your blissfully ignorant way.

All the best

Randy

buildingtexas@yahoo.com

MIKE DEBUSK | Aug 12, 2014

supertherm coating

I HAVE USED AND SOLD RADIANT BARRIER COATINGS FOR AROUND 20 YEARS THE FIRST BEING ( HYDRO-THERM ) THAT WAS SOLD AS A HOUSE COATING ONLY. THEN LATER I WENT WITH A COATING CALLED –SUPERTHERM-MFG BY SUPERIOR PRODUCTS IN SALINAS KANSAS.BY J.E.PRITCHET —AFTER READING ALL THE NEGATIVE COMMENTS BY MARTIN HOLLADAY CONCERNING NO SUCH THING AS RADIANT COATINGS I FELT THE NEED TO ADD MY 2 CENTS–MY FIRST COMMENT BEING –I WORKED FOR A MAJOR CHEMICAL COMPANY THAT I SOLD THIS PRODUCT TO FOR ABOUT 10 YEARS WITH OUT A SINGLE COMPLAINT AS TO WHAT IT COULD DO..BEFORE THEY WOULD PURCHASE IT THE THEY WANTED TO TEST IT IN THE LAB AND AFTER ALL THE TESTING..THEY WERE SATISFIED THAT IT WOULD DO AS STATED AND IT ACTUALLY DID BETTER IN SOME CASES. NOW SOME OF THE ENGINEERS SAID IT WAS A WHITE ELEPHANT PRODUCT EVEN AFTER SEEING THE TEST RESULTS HUMM I GUESS THEY WERE WRONG..BECAUSE THEY DIDN’T FIRE ME AND I’V WORKED THERE FOR ANOTHER 6 YEARS THEN RETIRED..AND YES THERE STILL USING IT…I’M NO ENGINEER BUT THE FACT THAT ALL THE FEED BACK FROM THE PEOPLE AND COMPANY’S I SOLD IT TO RE ORDERED. THE ONE THING THAT I MIGHT ADD ABOUT THIS PRODUCT SUPERTHERM IS THAT JAPAN BOUGHT SOME AND TRIED TO DUPLICATE IT THEM SELVES BUT COULDN’T AND HAVE PURCHASED THOUSAND OF GALLONS OF IT TO USE—YES I GUESS YOU CAN BELIEVE WHAT MARTIN HOLLADAY HAS TO SAY ABOUT THE PRODUCT BUT I KNOW BETTER.BECAUSE I STILL USE IT, WITH GOOD RESULTS. AND YES IT DOES A BETTER JOB WHEN FACING THE HEAT SOURCE…HAVE A GREAT DAY