Super Therm and Radiative Cooling Technology

What is Passive Cooling?

Passive cooling is basically cooling that doesn’t require a mechanical device. You can cool your home with air conditioning, however passive cooling allows you to take advantage of your climate to cool your home. Even if you require occasional air conditioning, which can help slash your energy consumption (source).

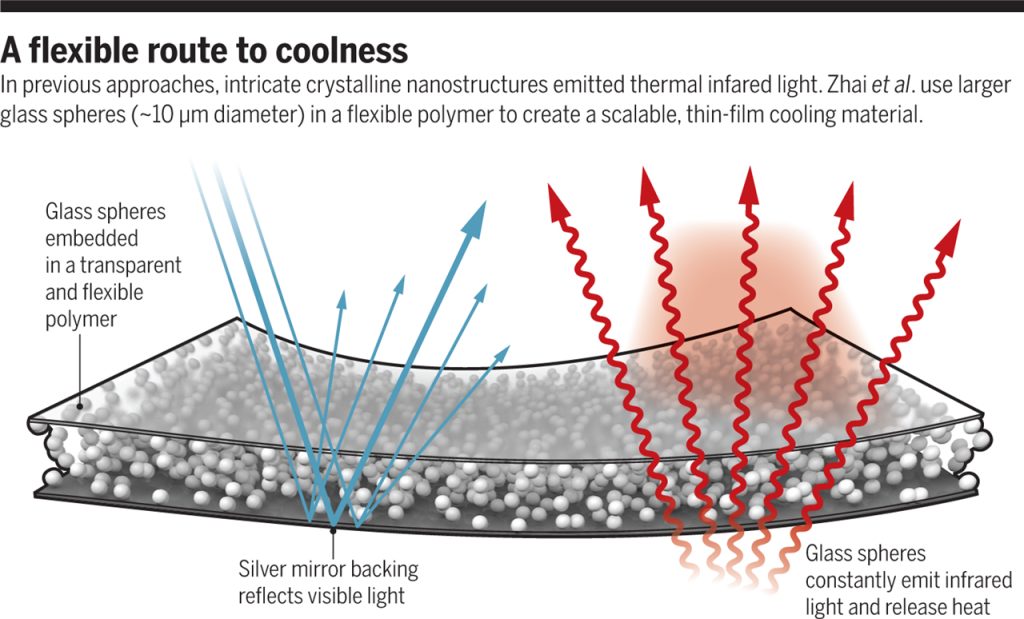

Radiative cooling (RC) is attracting more interest from building engineers and architects. Using the sky as the heat sink, a radiative cooling material can be passively cooled by emitting heat to the sky.

Passive Radiative Cooling is a natural phenomenon that generally occurs at night in nature because all nature materials absorb more solar energy during the day than they are able to radiate to the sky. At night, the surrounding environment cools the material to a temperature that is below the dew point or below freezing to form frost. This explains why you may see frost on your car windshield in the morning, even after the air temperature is above freezing. Passive Radiative Cooling (PRC) reflects enough solar energy to allow passive radiative cooling to occur during the day (source).

While the concept has been known for centuries, multi-layer optical films and materials science to develop a solar reflective film with passive radiative cooling capabilities. The selection of materials, they have optimized a property called selective emissivity which enables PRC to radiate heat into the sky in the precise infrared wavelength known as the atmospheric window. PRC enables 24/7 supplemental cooling and 10-20% energy reduction when integrated with building refrigeration and HVAC systems.

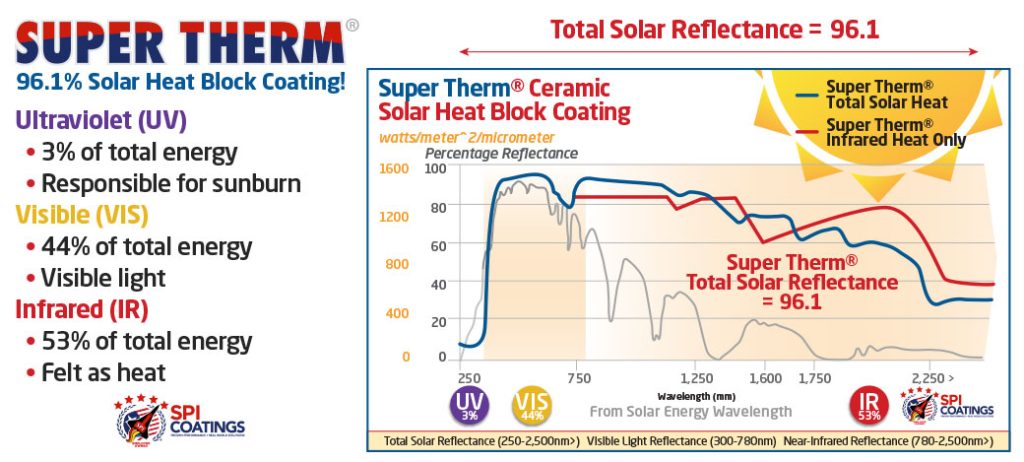

In one report, On the cooling energy conservation potential of super cool roofs stated “For example, when radiative cooling wood was applied to the mid-rise apartment building, material properties obtained in laboratory experiments for this wood have been inputted into the simulation model in the form of overall values. Specifically, the optical properties given for this cool material are thermal emittance (E) of 0.83, the solar reflectance (Rsolar) of 0.92, and the visible absorptance of 0.05. It was reported that new buildings had lower energy savings when applying cooling wood as the new building standards require the installation of better insulation materials.”. While this language talks about radiative cooling Super Therm® has an emissivity rating of 0.91 and solar absorption of just 0.039…making it a super cool solution proven for over 35 years.

Many surfaces emit (emissivity) more thermal infrared radiation between 8 to 13 µm (Mid to Long Wave Infrared) than they absorb from the sky. This imbalance can cool the surface below ambient air temperature. However, achieving sub-ambient temperatures during daytime, when cooling is required the most, also requires also achieving solar reflectance higher than 95% (source). Combining this high solar reflectance with selective infrared emittance requires engineered materials that have been in Super Therm® since 1989.

| Micrometre (μ) | 0.25 | 0.50 | 1.0 | 1.25 | 2 | 2.25 | 3 |

| Nanometre (nm) | 250 | 500 | 1000 | 1250 | 2000 | 2250 | 3000 |

.jpg)

Near Infrared // 0.75μ – 1μ (750 – 1000nm)

The NIR spectral band extends from wavelengths of 0.75μ to 1μ. This band includes applications in food testing, agriculture, biomedical instrumentation, and remote controls. For instance, pulse oximeters that measure oxygen saturation in blood use a combination of red (700nm) and IR LEDs (900nm) to determine the optical absorption of oxy- and deoxyhemoglobin. Self-driving cars use LIDAR to map their surroundings. LIDAR infrared optics typically operate at wavelengths of 905nm or 940nm. Night vision goggles and image intensifier tubes also work in the NIR band. Remote control devices also operate in this band, typically using 940nm LEDs for communicating with devices (Source).

Short Wave Infrared // 1μ – 2.5μ (1000 – 2500nm)

The SWIR band extends from 1μ to 2.5μ. A large part of this band is impractical for use because of intense absorption of water and carbon dioxide. However, this band does offer operational windows for optical communications at 1.3μ and 1.55μ where there is low transmission loss and low dispersion.

Mid Wave Infrared // 3μ – 5μ (3000 – 5000nm)

The MWIR band extends from 3μ to 5μ. MWIR is associated with thermal radiation that is emitted from surfaces, and most of thermometry is performed in the MWIR or long wave IR regions of the IR spectrum. The MWIR band is more suitable for indoor inspection of temperature in factories and furnaces, since ambient solar radiation can contribute to noise in these systems. Thermal cameras in airports and other indoor locations use MWIR infrared optics to detect the temperature of passengers.

Long Wave Infrared // 8μ – 12μ (8000 – 12000nm)

The LWIR band extends from 8μ to 12μ, although some classifications extend it further to 14μ. This is the choice IR band for outdoor thermal imaging, as it is less sensitive to ambient noise. LWIR is extensively used in military surveillance applications to the possibility of obtaining excellent contrast from background emitters. And for this same reason, LWIR cameras are used to look through foliage and detect human movement. With increasing usage of drones in surveillance and reconnaissance operations, the market for LWIR cameras has been steadily increasing.

Prevailing Challenges

Many possible problems must be explored when commercializing PRC techniques and materials, including environment, pricing, effectiveness, and endurance. Low cost is an essential consideration because it is connected to low-cost materials, widespread accessibility, and production procedures. Using precious metals (Ag or Al) as the sun reflecting coatings, as well as sophisticated production techniques and costly components, would raise the cost.

Polymers have received a lot of attention due to their low cost. However, considerable study is needed to build polymer-based PRC films for diverse applications, and most PRC films can increase their cooling capacity by optimization techniques.

Because of the poor conditioning density of PRC, wide areas are required to provide the cooling capacity, which enhances the price of the PRC equipment. At the same time, the endurance and consistency of PRC materials are significant challenges. Furthermore, in practical applications, management of waste, low energy consumption, and structural strength must be addressed.

PRC systems that do not require external power have grown quickly in recent years, gaining significant attention in both research and industry sectors. However, a year-long study should be proceeded to demonstrate material durability, periodicity, and financial viability (source).

Eli Goldstein from SkyCool declined to reveal exactly how much their SkyCool’s panels cost but acknowledged that they are currently “more expensive” than solar panels. “New technologies like radiative cooling are often more expensive,” he said. “People are very sensitive to first cost, and so that is another barrier to getting new things out there.” (source).

Mat Santamouris, Scientia Professor at UNSW stated in the article above “The payback period is not a single value. It varies as a function of the local climate, the type and characteristics of the buildings, the local cost of electricity and the way the material is applied. For conventional cool roofs, high reflectivity up to 85% and high emissivity in the whole IR spectrum, the payback period in Australia varies between 2 to 27 years. Super cool materials present a much higher energy potential than conventional cool roofs and about 20 to 50% higher initial cost. We expect to achieve a further decrease of the cost by using less expensive reflective components and also a tremendous increase of the energy benefits by modulating their optical properties in winter to provide heating. This is already achieved. We do not have a complete financial study, too early, but I expect a much lower payback period than the conventional cool roofs.”

While Mat’s response is interesting there are still many uncertainties about the new materials. Photos of the application, application style, longevity etc. Based on the data supplied above, Super Therm® works in warm to hot climates and shows a payback period of 5 years or less generally. Not all cool roof paints and materials are the same, Super Therm® is in a league of its own. It has a total solar reflectance of 96.1%, which is much higher than ‘conventional cool roofs’ and is able to block 367 to 4 BTU of infrared heat and at just 0.25mm is a low 0.559 W/m2/K transfer.

How does Radiative Cooling technology compare with Super Therm?

So what other considerations are there including:

- 20-50% energy reduction as tested by the Florida Energy Office

- Only coating developed with NASA

- NASA Tested and approved with Class “A” Fire rating – No fire spread

- Fire tested passed NATA Lab – Australian laboratories

- 35+ years lifespan with ongoing USA test

- Works even when dirty – white paints have been tested reduce reflectivity by 30% within 1.5 years

- Single coat wet 425µm (micron) easy application (mostly no base or priming coat required)

- 54% solids by volume – no need for 2 applications or priming – it’s not a paint; but a thick coating

- Tested successfully at 23, 50, 75 and 100°C

- 50-68% sound reduction

- Energy Reduction = Reduced KW power & electricity costs

- Safe and non-toxic for humans & animals

- US Department of Agriculture approval for use around food and potable water

- EPA approved

- Low VOC & Environmentally Friendly

- Global applications and solutions

- Over 10.3 million m2 applied across Japan

- Energy Star, LEED and CRRC Rated

- Water based

- Mould and Mildew resistant

- Moisture resistant

- No maintenance program required

- Easy to apply by airless, brush, roller

- Reduced thermal shock

The science looks good for Radiative Cooling Technology, however from our perspective in comparison to Super Therm® there’s some differences and questions.

Longevity of Super Therm® is proven. In any outdoor environment the ability for a films adhesion to lift and peel is possible, particularly if moisture gets underneath it.

The cooling benefits of radiative cooling look positive. We’ve seen the conversation regarding Winter Penalty. While this is nominal in relation to cooling benefits, it may seem radiative cooling may accelerate the heating costs in cooler climates.

Super Therm® is outstanding for its solutions at just 0.25mm and with a TSR of 96.1 and very low energy transfer of 0.559 W/m2/K means we believe we have a great product and solution. In some areas it may not match the new films but in other areas very much has strong and unique benefits.

We’re still not sure of the cost per metre in comparison either yet it could be 5x more in cost. We welcome new innovations and solutions and are looking forward to monitoring the potential new technologies progress.

- https://www.facebook.com/groups/MyEfficientElectricHome/permalink/5055877614456641

- http://radi-cool.com/

- https://www.nature.com/articles/d41586-019-03911-8

- https://www.abc15.com/decodedc/technology/asu-student-looks-to-prevent-phone-overheating-with-cooling-phone-case-charger