Condensation Control

Super Therm® heat block coating used for condensation management

Condensation Report pdf

Coatings from Superior Products International II, Inc. are distributed by NEOtech Coatings Australia are designed to resist condensation, moisture, mildew and mould. Enamo Grip can be applied to damp surfaces without compromising their effectiveness.

Fight condensation with:

- Super Therm® – Our best selling insulation coating prevents mould and mildew

- HPC – Specially designed for hot pipes and high temperature situations

- Enamo Grip – Protects concrete and steel in wet areas

Condensation happens when warm moist air comes in contact with a cold surface. Condensation is a surface phenomenon. The hot air is not the problem, the cold surface is. Therefore, in order to prevent condensation, the temperature differential between the air and surface must be reduced. When the warm air touches the cold surface, it begins to cool down. When warm air cools, it cannot hold the moisture inside of it and this moisture will fall out of the air as it cools if in the sky, it is called rain or against a cold surface it is called condensation.

Condensation occurs only when moist air reaches the saturation point by the presence of a cold surface. The point of condensation developing on the surfaces is directly related to ambient air temperature and relative humidity. From these two factors is derived the dew point that dictates the condensation level.

On a surface, Super Therm® is applied to reflect and repel ambient heat off the coated surface while stabilising the surface temperature and to maintain the smallest difference of temperature between the room ambient and surface temperature of the surface. The smaller the spread of temperature, the less chance of meeting the dew point and forming condensation of the cool surface. Maintaining a 2.7°C (5ºF) temperature above the dew point is the goal to avoid condensation.

Warmer air holds more moisture which relates to a higher dew point and creates condensation at higher ambient temperatures. Colder air holds less moisture which relates to a lower dew point and causes condensation at a lower ambient temperature.

Two ways to prevent condensation:

1. If you have a fan and turn it on and the fan blows air so that the warm air cannot touch and set long enough next to the cold surface, it cannot cool down and moves pass the cold surface and will not have any condensation. This means that if someone is having a condensation problem and you want to stop the condensation before you can get to the location to apply the coatings, then have them set fans in the room or area and blow air or wind to move the warm air.

2. When we apply Super Therm or HSC over a surface when the surface is dry, the coating will not allow the warm air to come in contact with the cold surface because it is a barrier between the warm air and the cold surface. If the warm air cannot touch the cold surface, the warm air cannot cool down to begin to condensate.

In areas where the humidity level is very high (80% or above) and the pipe or surface is very cold like -12°C, then the thickness of the HSC will need to be 12mm or more. Usually in this range, we use HSC.

In normal conditions where you will find condensation would be ambient temperature of 0°C and relative humidity of 65%, the point of condensation when the warm air cools down to 24°C is when the condensation will appear. The HSC coated at 3mm with an overcoat of Super Therm® will prevent this from happening. The reason is because the warm air cannot heat the surface of the Super Therm® and this heat cannot penetrate into the HSC to come into contact with the cold surface to allow the warm air to cool. As long as the coating repels the warm air off the surface and keeps the separation of warm air to the cold surface, no condensation can happen.

Usually in Australia condensation is more common in winter as the metal roof cools with the night air. When warm air comes into contact with a colder surface, it cools down and can’t retain the same amount of water vapour. The excess water vapour is released and forms condensation.

Super Therm® helps prevent condensation and thus corrosion, mould and energy use.

On a traditional roof, without protection, condensation builds up on the metal underside of the roof. It then drips onto the ceiling below. The fibreglass batts below act like a giant sponge. It has been noted as the batts absorb the moisture from above ceiling stains can appear. There have been cases that the ceiling can become so wet that it is in danger of caving in. This also means the value of fibreglass as an insulator has also deteriorated.

When Super Therm® is applied to the condensation side, generally inside, it prevents the water vapour build up. If the exterior facing the sun has been coated with Super Therm®, then the underside is colder. This would require 8mm of HPC® with an overcoat of Super Therm® to block the trapped warm/moist air from touching the cold surface.

Note: Anytime warm/moist air is allowed to come into a cool room, you will have condensation because the warm/moist air will begin to cool and you will have water droplets everywhere anyway, but not dripping from the ceiling.

Super Therm® has many other cost-reducing, profit-enhancing benefits. Condensation and moisture inside buildings quickly deteriorates existing insulation materials, and can be a breeding ground for disease, damage internal structures, causes corrosion and drips water under unprotected areas causing inconvenience.

Super Therm® on houses, storage containers, verandahs and cold water pipes, feed bins etc will eliminate condensation and moisture, extending the life of existing materials and preventing moisture damage. Use of Super Therm® on Bin Feeders in agriculture for example, also prevents condensation and moisture contamination of the feed, resulting in less feed waste. Other benefits include:

- Stops container rain or condensation inside shipping containers

- Reduce risk of condensation on cold water pipes

- Protect feed bins to reduce condensation and feed degradation

- Insulate freezers or refrigeration units to protect goods and reduce costs

- Prevents condensation and corrosion in air conditioning systems, pipelines, tanks, ships, etc.

- Protect goods by insulating long haul trailers designed to carry perishables

- Reduce heat stress during animal transportation by applying to vehicles

- Reduce energy costs and increase comfort by coating roofing and interior/exterior walls to keep heat in during winter or heat out during the summer

- To provide a fire-resistant coating for substrates. Super Therm® has a “0” fire and smoke spread and will not contribute to flame providing added benefits and safety.

CASE STUDY

Super Therm® on Poultry Houses

- Fact: Reduced attic temperature by 16.7°c (30° F) – Benefit: Death rate of chickens dropped by 75%

- Fact: Chickens were heavier at the end of growth season – Benefit: more case value per bird

- Fact: Current insulation materials become loaded with moisture form condensation and must be replaced every 5 years. Super Therm® eliminated condensation and will perform for 20 years without concern for reinsulation – Benefit: Saves the cost of reinsulation 4 times over 20 years of the life of the house, insulation materials and labour savings. Example

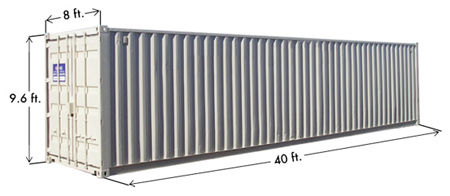

Super Therm® Coverage for a shipping container

Each container has 2 sides / 2 ends and the roof

- Standard 20’ x 8’ x 8’ = total area to cover 56.5m2 – 608 f2 (60m2 approx.) 2 pails needed

- Hi cube 20’ x 9.6’ x 8’ = total area to cover 68m2 – 729.6 f2 (70m2 approx.) 2 pail needed

- Standard 40’ x 8’ x 8’ = total area to cover 101m2 – 1088 f2 (102m2 approx.) 3 pails needed

- Hi cube 40’ x 9.6’ x 8’ total area to cover 122m2 – 1305 f2 (122m2 approx.) 3 pails needed

Currently we sell full 5 gallon US (18.9 litres) pails. We recommend using Super Therm® on the floor internally as this neutralises any contaminants in the timber and provides additional floor insulation. Super Therm® has a coverage of 40-45 m2 per pail depending on application.

Note: if container has rust it needs to be thoroughly cleaned and we suggest a coat of Rust Grip® before you apply Super Therm®. For the ultimate protection then apply Enamo Grip over the top as the perfect protection against the elements.

Contact us below if you wish to purchase Super Therm® for your shipping container project.

Recommended coating system for shipping containers

The SPI Coating System applied to the shipping containers consists of the following: After thorough pressure clean and drying, Super Therm® is applied directly to the exterior walls and roof of the container, and HSC® Coating (recommended) and Super Therm® applied directly to the interior walls and ceiling of the container.

In the real world environment with factors of condensation, air infiltration, moisture absorption, and thermal bridges, the SPI Coating System provides an insulation benefit for the shipping containers in cool to hot environments.

The SPI Coating System provides insulation against radiation heat transfer and conductive heat transfer, blocks the absorption of moisture, air infiltration, condensation, and mould and mildew, and is a fire resistant coating with zero flame spread and zero smoke.

NEOtech Coatings Australia are pleased to be a part of and to support your efforts to develop energy efficient and affordable structural systems for use in home and commercial construction using shipping containers.

Container Condensation

Condensation on a container roof and walls is due to the fact the underside of the roof’s substrate becomes colder than the opposite surface. If Super Therm® Ceramic Insulation Coating is applied on top of a container or verandah, facing the sun and blocking any heat load into the metal this solves one part of the challenge.

The other part is also using Super Therm® or HSC on the underside to stabilise ambient temperatures on the inside of the substrate as well.

In airflow environments or locations where the underside remains near ambient the better the position to control condensation. When the warm air hits the substrate and sets, it cools and when it cools, it cannot hold the moisture and it shows as condensation on the side of the warm air.

As warm air cools, it drops out it’s moisture. Because the heat has transferred through the substrate it presents as moisture on the cool side. Heat is drawn to cool. In all situations, if there is a 2.7°C difference between ambient and a surface with the surface being cooler, you will have condensation. So, it is a situation where you check the temperatures of ambient and the surface to see if you have a problem with condensation.

Then if the difference between the ambient and the surface is wide you have to start using a product like Hot Pipe Coating or Hot Surface Coating to help control the condensation because you need thickness to keep the ambient (hot/humid) temp away from the surface temp of the unit, roof or wall.

When you get over a 11°C difference between the interior and exterior of a wall, you may need some thickness of insulation to prevent condensation like HSC.

The goal is to block the warm air from setting on the surface of anything cool, Super Therm® helps to throw off the radiation during the day by using emissivity to release the warmth off the surface and heat load. It also slows down the escape of heat during the night. Application on the opposite surface wth Super Therm® prevents the substrate being extremely cool which therefore prevents the large temperature differences that convert into moisture and condensation.

Super Therm® sandwiches the metal to keep the sheet ambient and also provides future proofing with tough protection.

The Super Therm® blocks the initial HEAT LOAD which is the beginning of the heat transfer measurement. It is a fact, that if you “reduce the amount of heat in the initial loading, you have reduced the amount of heat “available” for transfer into the shipping container”.

HPC for Cool Room Condensation – 30°C variation

The Challenge: A client was looking to stop condensation on a wall that was an office and the room was 22°C. The other side of the wall was a cool room at -15°C with panelling. Both walls are interior to the building however for this conversation the office wall is the exterior wall.

HPC Solution from SPI Coatings

When you get over a 30°C difference between the interior and exterior of a wall, you need some thickness, so you are only interested in the exterior side of the wall.

Why, because the hot moisture air is only on the exterior wall.

When the warm air hits the wall and sets, it cools and when it cools, it cannot hold the moisture and it shows as condensation on the side of the warm air. As warm air cools, it drops out it’s moisture.

The interior is cold and no moisture as the air conditioning unit pulled all the excess moisture out of the air and cool air does not hold moisture. You must prevent the warm moist are from setting on the cold common wall between interior and exterior.

To do this, you must apply HPC® for thickness to 13mm dry thickness and over coat with Super Therm®.

This blocks the warm air from setting on the surface of anything cool, the Super Therm® helps to throw off the radiation by using emissivity to release the warmth off the surface.

You must have the thickness of the HPC® to prevent the wall surface with Super Therm® on it to ever being cool that would cause the warm air still covering the exterior wall during the warm air laying on the wall and then being thrown off by Super Therm®. You would still have some condensation without HPC®.

NEOtech Coatings Australia are pleased to be a part of and to support your efforts to develop energy efficient and affordable structural systems for use in home and commercial construction using shipping containers.