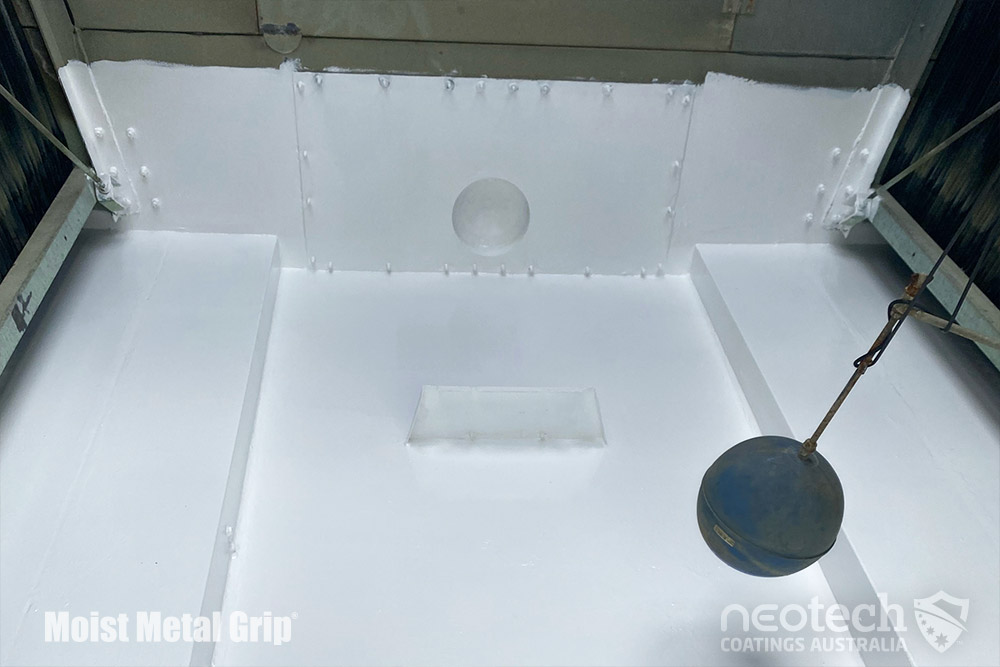

Water cooling tower corrosion treated with Moist Metal Grip

Industry: Cooling and Cold Storage

Location: Yallah, New South Wales, Australia

Products: Moist Metal Grip

Global Partner: NEOtech Coatings Australia

Our Australian/New Zealand Distributors, NEOtech Coatings were approached by Coolblue Airconditioning in Yallah, New South Wales who were looking for a solution to corrosion in a water cooling tower’s air-conditioning system. The cost of maintenance to remove the tower with a new structure was prohibitive for the client’s budget and Moist Metal Grip® was introduced as the best solution for the challenge.

Moist Metal Grip® will have very good, long term success. You should get 5-10 years corrosion protection in a submersed moisture environment for both fresh and/or saline water

SHANE STRUDWICK, CEO, NEOTECH COATINGS

Simple application recommendation

Make sure the surface is clean, no dust, salts or contaminants etc. SPI Coatings the manufacturer recommends cleaning the surface with citrus cleaner to release dirt or TSP (tri-sodium phosphate). Definitely treat as per the instructions if there’s any salts.

You can apply Moist Metal Grip® if the environment is still moist as it pushes the moisture away. Better if it is dry but not essential.

- The first coat apply by brush so you can really push the coating into the metal substrate and existing corrosion and pores.

- The 2nd coat can only be applied when the 1st coat becomes tacky to the touch and has little to no transfer of the coating.

- If the 1st coat is allowed to cure more than 3 days to where it is no longer tacky, the surface must be lightly sanded to make it tough before the second coat is applied.

About Moist Metal Grip

Moist Metal Grip® is a two-part (2 component), touch adherent, epoxy coating which produces a hard, yet flexible coating film designed for application on dry, moist, wet or submerged surfaces for protection against corrosion and chemicals. Moist Metal Grip® was developed to be applied to metal surfaces that cannot be dry enough to use Rust Grip® or already experiencing moisture or condensation that cannot be stopped and dried. Find out more >

This provides long term solutions and maintenance to much more than water cooling towers. Contact SPI Coatings for to help you with any moisture base corrosion challenges.