Poland Pantech with Super Therm Ceramic Coating

Industry: Transportation

Location: Krzeszowice, Poland

Products: Super Therm®

Global Partner: HTH-NOVOTECH LTD

Reduced energy consumption and an average 4°C – 7°C lower temperature

Goal of the test:

Showing energy savings possible to gain after application of Super Therm® coating on the roof of refrigeration truck.

Procedure of the test:

Conducted test relied on comparison of cooling down loading space of two identical refrigeration trucks, one with roof coated with Super Therm® coating (0,25mm thickness), and another one without this coating. Both trucks, standing next to each other were exposed to sun radiation when their refrigeration units were working.

To obtain absolutely objective results of the test trucks weren’t loaded.

Application of Super Therm® coating was done 3 months before carrying out the test, within this time car was normally used.

Data about the trucks:

- Make – Man TGL 12.201

- Year of production – 2006

- Loading space producer – Lamberet

- Capacity – 14 pallets

- Refrigeration unit – Supra 750

- Roof area – approx. 16m2.

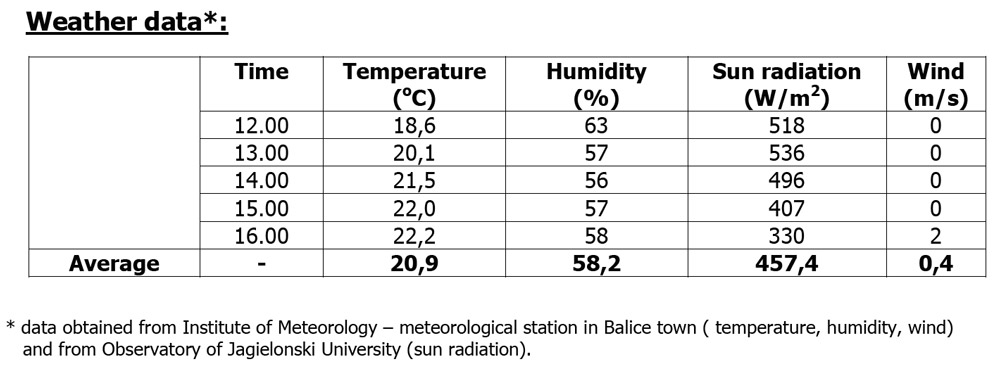

Data about the test:

Place of the test – Krzeszowice, Poland

Date of the test – 20.09.2009

Duration of the test – 4,5 hours

Test run:

Both trucks were taken out from garage about 10 a.m. then for two hours were standing outdoor with refrigeration units turned off. Actual test began at 12 p.m. by turning on refrigeration units in both cars, and lasted till 4.30 p.m.

Deactivation of refrigeration units were fixed on temperature -22°C, and activation on temperature -18°C.

Comment:

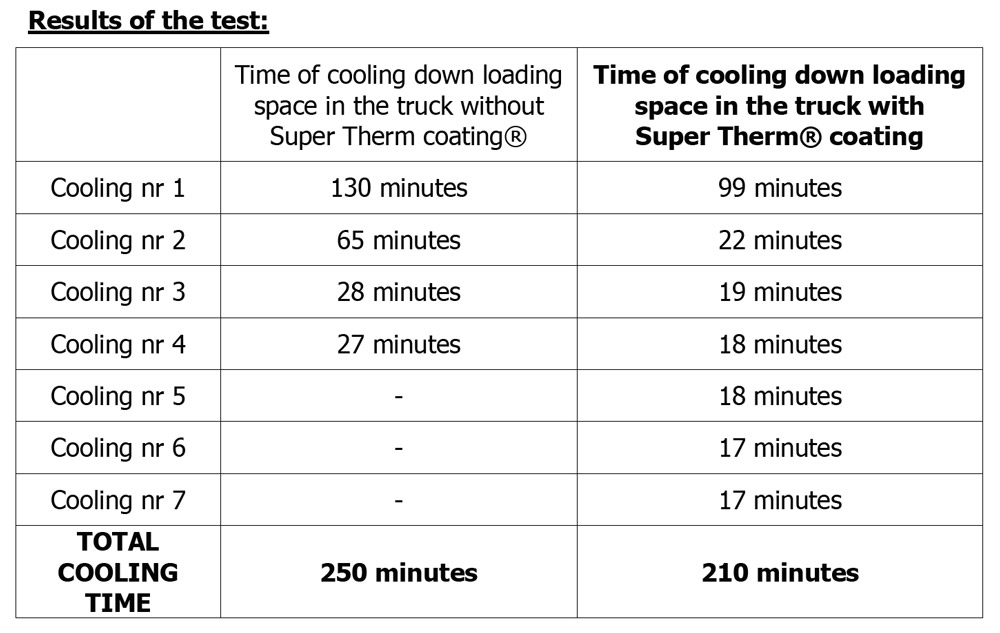

Even though the amount of activations of cooling aggregate in truck with roof coated with Super Therm® was higher that in case of truck without Super Therm®, however total time of refrigeration unit work was 40 minutes shorter for truck with roof coated with Super Therm®.

40 minutes shorter running time – energy savings

As seen in above test results, application of Super Therm® enable obtaining desired temperature in the loading space much quicker, what enhance conditions of carried goods (especially food). Moreover, Super Therm® application positively influence operation of refrigeration unit, extending its life span.

It must be noticed, that the test was carried out in the end of September, so we can assume that energy savings during summer time will be higher.

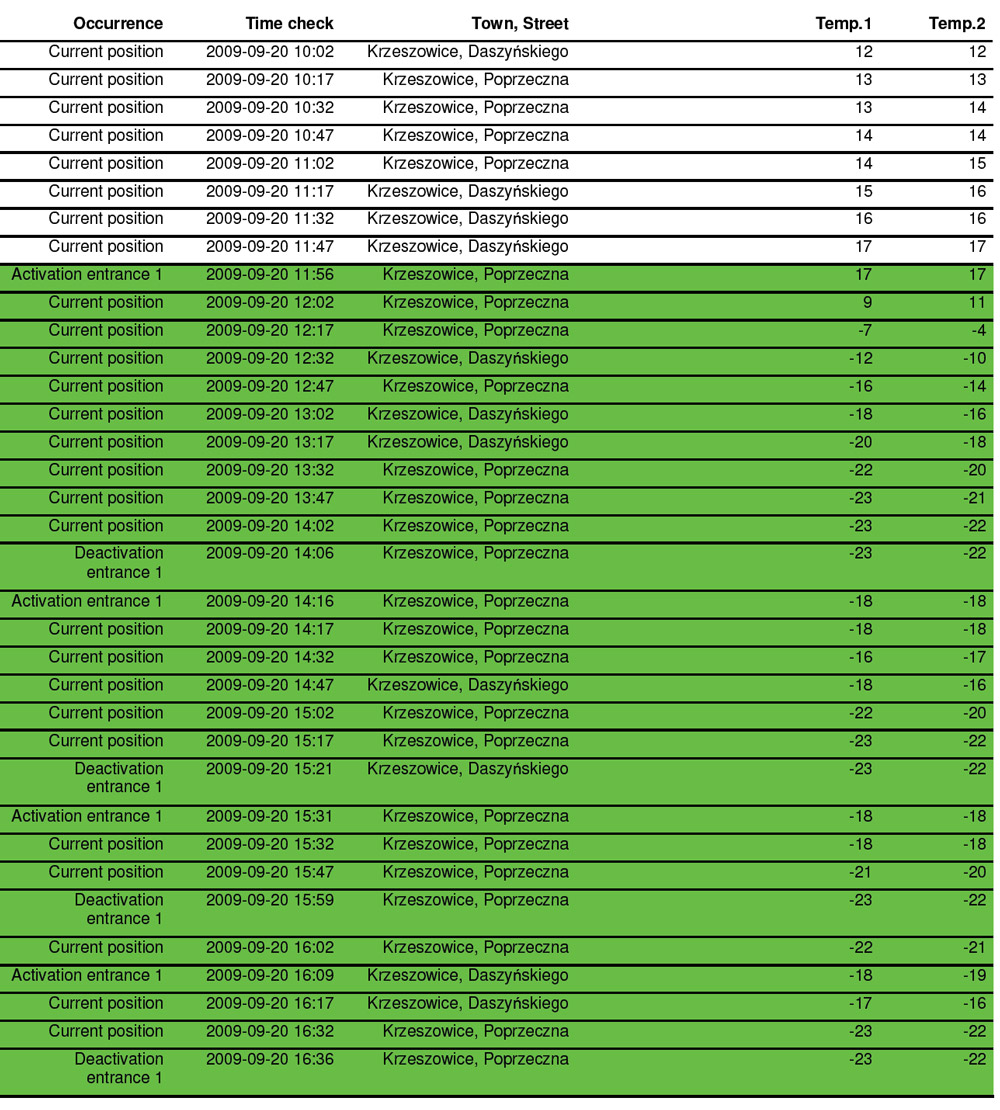

GPS report from the refrigeration truck with roof not coated with Super Therm®.

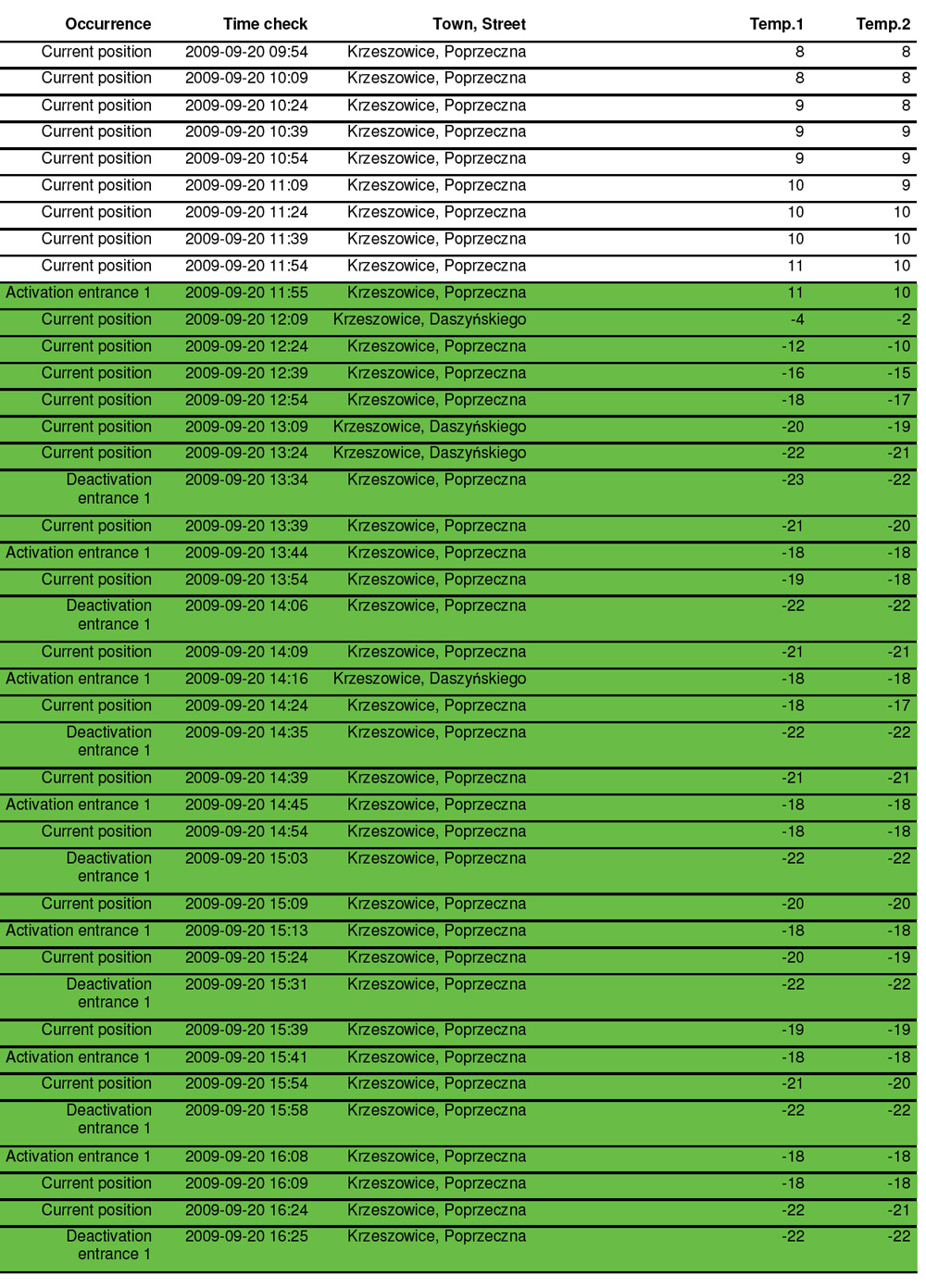

GPS report from the refrigeration truck with roof coated with Super Therm®.

Comment:

As seen in the above reports, even before commencement of the actual test (between 10 a.m. and 12 a.m.) temperature of the loading space in truck with roof coated with Super Therm® was on average 4°C – 7°C lower than loading space in the truck without this coating.

Average 4°C – 7°C lower temperature