HPC® Coating – Pemex Offshore Thermal Insulation

Industry: Oil, Energy & Mining

Location: Gulf of Mexico

Products: HPC® Coating, Enamo Grip

Global Partner: SPI Coatings & CS&A - SPI Coatings Distributor

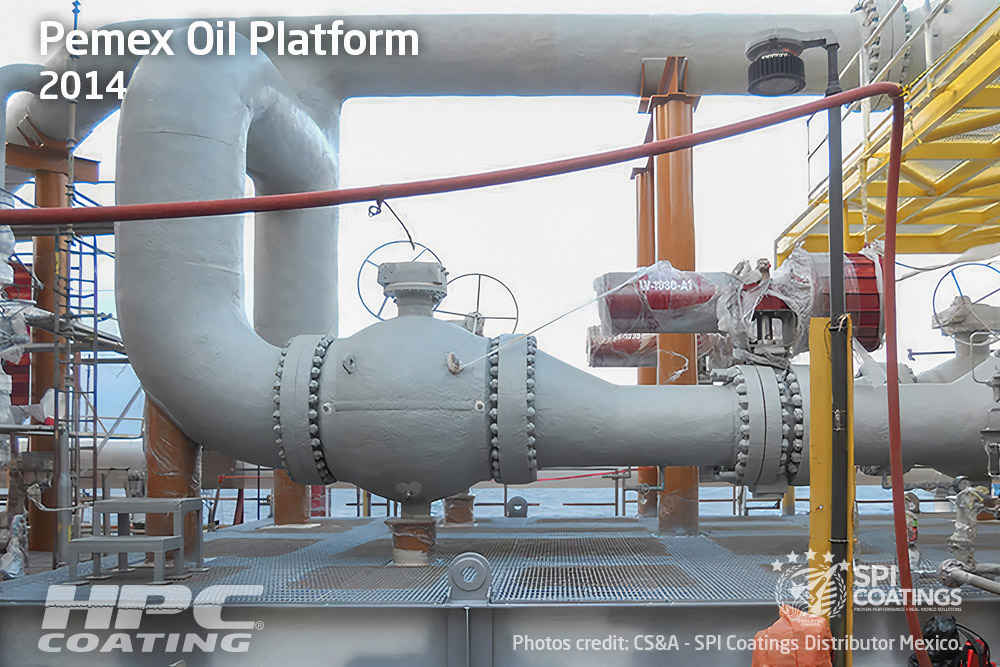

SPI Coatings’ application on Pemex Oil’s offshore crude piping in the Gulf of Mexico was applied in 2014. This showcases the coatings’ ability to withstand harsh oceanic conditions while preventing corrosion and maintaining significant temperature reductions over time including withstanding hurricane winds.

Mexico’s Pemex Offshore Crude Piping in 2014 with HPC® Coating’s fresh application with Rust Grip® corrosion prevention and Enamo Grip® protective industrial coating. An average temperature reduction of 55% to a surface below 50°C.

Mexico’s Pemex Offshore Crude Piping in 2024 showcasing HPC® Coating‘s ability to withstand harsh oceanic conditions while providing energy efficiency, reducing maintenance and preventing corrosion and still keeping the average temperature reduction. No deterioration and no drop in performance. Photos: CS&A – SPI Coatings Distributor

Innovative thermal insulation and corrosion protection solutions offered by SPI Coatings

With over 35 years of proven performance in both field and laboratory settings, these coatings are designed to deliver significant energy savings, decarbonization, and long-lasting durability. The range of products, including HPC® Coating and Rust Grip®, provides comprehensive protection against corrosion under insulation (CUI) while maintaining surface temperatures and reducing maintenance costs. This highlights SPI’s commitment to enhancing energy efficiency, asset longevity, and personnel safety in demanding industrial environments.

Key benefits include:

- Energy Savings: SPI’s coatings offer up to 49% energy savings, contributing to lower operational costs and environmental benefits.

- Temperature Control: The coatings can handle a wide range of temperatures, from ambient up to 650°C, with specific products like HPC®, HPC®-INT, and HPC®-HT designed for different thermal applications.

- Corrosion Protection: The combination of Rust Grip® for corrosion prevention and Enamo Grip® for industrial protection ensures durability, even in harsh conditions like offshore environments. The products demonstrated no deterioration or performance drop over a 10-year offshore service in the Gulf of Mexico.

- Safety and Durability: These coatings not only reduce energy costs but also improve personnel safety by lowering surface temperatures, preventing corrosion under insulation (CUI), and extending the lifespan of assets in sectors like oil and gas.

This highlights the proven field and laboratory success of SPI Coatings in the most extreme environments, positioning HPC® Coating as a reliable solution for industries aiming to enhance energy efficiency and asset protection.