A Low-Emissivity Coating That Really Works

Some sectors and people rely on old, misinformed articles to try validate their arguments. But what’s even stranger articles like this one aren’t even comparing products correctly and have conflicting views. The article makes references to insulating paints yet the whole article talks about internal radiant barrier coatings. They are nothing alike. It could easily be speculated it looks like a promotion piece for SOLEC who manufacture internal radial barrier coatings and designed to potentially discredit cool roof external coatings. Even the opening paragraph from this article is taken from the Alex Wilson quote here “Ceramic Paint-On Insulation: Does It Work?” or vice-a-versa. Quotes also from Andre Desjarlais of Oak Ridge National Laboratory rightly so work on false and misleading products, yet Andre also acknowledges the benefits of cool roof coatings. Let’s break it down and get to the truth of this very confusing article! Be mindful the website this article is from actually promotes cool roofs called the Environmental News Network.

BUILDING GREEN 12 MARCH 2008

By Greg Zimmerman, Executive Editor

https://www.enn.com/articles/32849–a-low-emissivity-coating-that-really-works

To say that there is a lot of hype about insulating paints and radiant barrier coatings is an understatement. The Internet is rife with claims of paints that dramatically reduce heat transfer usually based on some technological magic spun off from NASA. While these products may have some relevance in the extreme conditions of outer space, manufacturers of paints containing ‘ceramic beads’ or ‘sodium borosilicate microspheres’ are making claims that defy the laws of physics–and independent test results–when they claim they can save significant energy in buildings.

We’ve seen all the hype, imitators and deception in the marketplace as well. One of the worst articles for this is on Wikipedia which we highlight all the wrong facts about insulation coatings and paints along with misinformation. The real Super Therm® is very much based on science and physics of micron sized ceramics that reflect the 3 heat waves and prevent heat load. It’s very precise formulation…again with independent results. With regard to NASA…enjoy the read.

Well-engineered coatings with metallic particles can reduce radiant heat transfer, however. LO/MIT-II from SOLEC Solar Energy Corporation has a long track record of success and is, at least for now, the only such product made with a water-based, low-volatile-organic-compound (VOC) formulation.

This is the framework for SOLEC’s product. With regard to the absolute comment ‘...the only such product made with a water-based, low-volatile-organic-compound (VOC) formulation.’ could be for internal radiant coatings…The real Super Therm was developed between 1989-1995 and was always water based with a VOC rating of just 67 grams/litre. It was approved by the EPA and tested by the FEO. Not sure if SOLEC’s products have the same independent testing by the Florida Energy Office.

Radiant-heat control products can reduce heat transfer in attics and in certain mechanical system applications. To be effective, however, they must produce a low-emittance surface, like the low-emissivity coatings on high-performance windows, and the best way to get that low emittance is with a low-emissivity foil product. Foils come in rolls adhered to plastic films for strength or attached to the underside of roof deckings. The best of them have emissivities as low as 0.03 when they are news as they get dirty and scuffed their performance declines.

Whereas cool roof external coatings need to be high emissivity. Windows are designed to still let in light which makes up 44% of total heat. Reflecting heat at the roof’s envelope is critical to keeping a cool substrate, whether that’s a roof, wall or anywhere else heat can penetrate. Foils are unable to go on the outside of a roof so therefore aren’t able to manage moisture or dirt as their performance declines. Super Therm‘s high emissivity, ability to block 99.5% of infrared and UV and works in the toughest environments on virtually any substrate makes it the perfect solution.

There are no paint-on or spray-on coatings that perform as well as the foil products, but for applications where it just isn’t feasible to roll out a shiny film, a coating may be the best option.

Okay, so what the article’s eluding to is if you can’t put in foil try the internal radiant barrier coating. Therefore this is based on keeping heat in, not out. That’s opposite to cool roof coatings and paints. This article is based on interior coating systems…not exterior! We’re not comparing apples with apples yet it’s endeavouring to stretch and connect foil and internal coatings are better than external cool roof coatings. Got it…jumping the shark!

ASTM Standard C 1321 defines an ‘interior radiation control coating system’ (IRCCS) based on a measured thermal emittance no higher than 0.25. In 2006 the Reflective Insulation Manufacturers Association (RIMA), which represents suppliers of both foil and coating products, hired insulation specialist David Yarbrough, Ph.D., P.E., of R&D Services to determine the emittance of a range of coatings on the market.

Again interior coating systems…not exterior! Apples with apples.

Based on independent testing of 17 products from ten manufacturers, Yarbrough found four that met the ASTM definition of an IRCCS. Three of these four are solvent-based, making them high in VOC emissions. LO/MIT-II (the name is a contraction of ‘low emittance’) is the exception, with a VOC level of 170 grams per liter.

Would love to see where the results are for the 17 independent tested products for internal coatings. While Super Therm is not designed for interior use it does have a very low VOC of just 67 grams/litre. Regardless this article isn’t even related to what cool roof coatings offer.

Of the other three products, one is LO/MIT-I, also from SOLEC, which has similar radiant-control performance to LO/MIT-II but relies on the hazardous solvent xylene, leading to overall VOC levels of 660 grams per liter. This solvent-based formulation is slightly cheaper than LO/MIT-II and is used as an exterior coating on metal structures, according to SOLEC president and CEO Robert Aresty. The other two products with high VOC levels but with emittance below the ASTM threshold are Radiance e-0.25 from BASF and HeatBloc-75 from STS Coatings. These two products have similar characteristics. HeatBloc-75 was ‘reverse engineered’ from Radiance, according to company owner Cayce Kovacs, though she adds, ‘We never manufactured it from the same formula as them.’ STS is working on a water-based version of HeatBloc-75 and expects to make it available during 2008. A fifth product, Sherwin-Williams’ E-Barrier, has thermal emittance slightly above the ASTM threshold and moderate VOC levels. *RIMA’s test results for all these products were consistent with the manufacturers’ claims. In Texas, where there is an established network of radiation control coating companies, the installed cost for these products ranges from $0.25-$0.40/ft2 ($2.70-$4.30/m2) in new construction, and $0.40 to $0.90/ft2 ($4.30-$9.70/m2) in retrofits.

‘This solvent-based formulation is slightly cheaper than LO/MIT-II and is used as an exterior coating on metal structures’. So basically their ‘low-emittance’ external coating means it absorbs heat but won’t release it. That’s opposite to the objective of a cool roof coating. Love to see the data on that. Really don’t think I want a product in my roof that’s declared ‘similar radiant-control performance to LO/MIT-II but relies on the hazardous solvent xylene, leading to overall VOC levels of 660 grams per liter’...that meets the needs of the ‘Environmental News Network’ to promote. Both hazardous and will smell…not healthy at all. While this article focuses on VOC’s there’s no information regarding temperatures, efficiency and results. Zero! Super Therm was tested by the Florida Energy Office with energy savings of 20-50% in 3 different locations. It is a high performance, safe, proven external heat block coating that is blocks most of the solar heat. Tested and in part developed with NASA…really nothing alike the way the article sets it up.

Radiant Control Coatings

*Per RIMA 2006 testing

**Does not meet the ASTM definition of an IRCCS; company literature claims a value of 0.29 to 0.32, depending on the substrate

Unlike these metallic coatings, all the rest of the products tested those with ceramic-bead technology – created high emittance surfaces. Yarbrough notes that painting a high-temperature metal pipe with these paints would most likely increase heat loss by increasing the pipe’s surface emittance (even while making the pipe feel cooler to the touch). The manufacturers of most of these products don’t make any specific emittance claims.

Wow, this is a very mixed statement. So the article is trying to discuss internal radiant control coatings so they’ve taken ‘ceramic-bead technology’ for external use which does have high emittance, like Super Therm and now we’ve moved away from roofs to metal pipes. What the? Thermal emittance is about how quickly a coating can ‘release heat’ from the surface that has been absorbed. It also is designed to block heat from entering. I’m not sure what pipes have to do with solar heat block and insulation coatings. Andre Desjarlais states “A Cool Roof: Roof surface that has a high solar reflectance and a high thermal emittance” (Source, pg 9). Cool roof coatings and paints are designed for high emittance why talk about metal pipes? Maybe the goal of this article is to mesh weird concepts and get the result that cool roof products don’t work through confusion by a promoter of internal radiant barrier coatings.

It’s important to note that with pipe insulation you need to know the internal temperature of the pipe, diametre, thickness and average ambient temperatures to insulate. You can’t give a surface emittance without that information. For more information see our HSC and HPC coatings for high temperature pipe insulation.

Some of these manufacturers do publish insulation values, however-in one case as low as U-0.017 W/m2K, which translates to an R-value in inch-pound units of 8.5 per inch. Even if that claim is to be believed, at the recommended 6 mils of thickness it provides a negligible R-value of 0.05. Researchers at Oak Ridge National Laboratory did a side-by-side test of two exterior roof coatings, one loaded with those beads and one a standard latex paint. We saw no difference between them said Andre Desjarlais of Oak Ridge. ‘All the benefit was due to color and reflectance.’ Periodically, companies get in trouble for making spurious claims, as in a 2002 case in which Kryton Coatings signed a consent decree regarding unsubstantiated claims that its Multi-Gard coating system provides R-20 in insulation value. ‘You beat one down, and others pop up’ complained Desjarlais.

Poor Andre Desjarlais’ comments are used in mixed context. Now we’ve gone back to external cool roof coatings. Super Therm at just 0.25mm is rated at 0.559 W/m2/K (ASTM E1269 BTU Conductivity testing and results)...Proven and tested. Andre is a pro-cool roof coatings expert and he’s correct that companies make unsubstantiated claims (see our Wikipedia article). This however doesn’t mean every product is the same. Ridiculous that the author of this article has mashed up so many issues to validate a bizarre argument. Super Therm isn’t a ‘beaded’ or latex paint and has proven it’s as a formulated, 4 ceramic solar heat block coating with high performance and results. Again read through our materials, testing and energy savings results and you’ll see there’s coatings with 100% absolute integrity and results.

While no coating can provide a meaningful R-value, LO/MIT-II and its peers can reduce heat transfer by increasing surface reflectance and reducing emittance. These coatings have a metallic sheen that limits their applicability to places where appearance isn’t a concern. Other products offer similar benefits, to a lesser degree, in normal-looking paint by reflecting only invisible, infrared radiation. These can be used on exterior walls to reduce heat gain when adding insulation isn’t feasible. Oak Ridge tests of Coolwall from Tex-Cote found the potential for a 10% reduction in wall heat gain, according to Desjarlais.

Nadav Malin

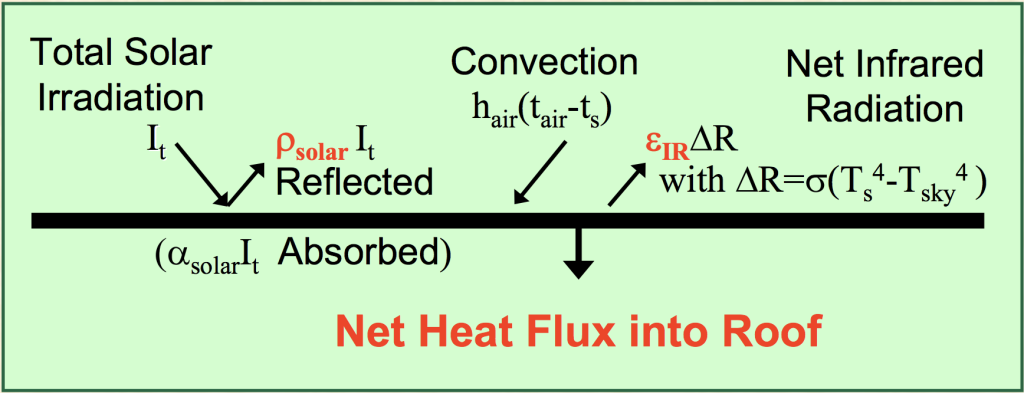

True, finally, no coatings can make any R-value claim so why make a statement about ‘meaningful R-value’. This article looks like its written to promote LO/MIT-II which is designed for internal use and discredit every other product in the marketplace. Really we’re just not sure on it’s performance as the coating’s article gives no actual results. The coating doesn’t look great visually so that’s why ‘their applicability to places where appearance isn’t a concern’. Unlike a cool roof external coating that needs to be functional, proven, and aesthetically appealing. Even the reference by the author to Oak Ridge on one product ‘Coolwall’ (DOE study which showed savings ranging from 4.2-21.9%…lets average at 10%) in the marketplace means ‘all coatings’ don’t work…NOT TRUE! Again an internal coating doesn’t need to focus on visual heat and the absolute meshing of conflicting issues and products is designed to confuse the reader…unfortunately when people read this who are ‘anti cool-roofs‘ they only see what’s written but don’t understand the context and the lack of genuine facts. A true cool roof coating will be measured in U-values to gain the Net Heat Flux into Roof based on W/m2/K.

Want an independent report on cool roofs by the same reference that this author has stated? Read Andre Desjarlais‘ 2009 presentation from Oak Ridge National Laboratory, US Department of Energy. The Florida Energy Office rated Super Therm as having 20-50% energy savings in 3 different locations.

Reduces cooling loads:

• Reduces peak energy demand

• Can reduce ambient temperature in an urban setting (urban heat island)

• Improved air quality

• Further energy savings

• Cool roofs being included into energy codes

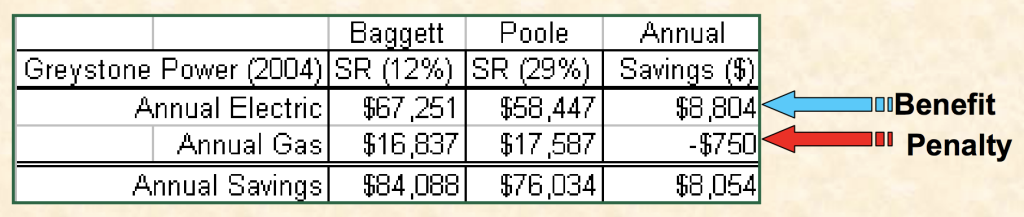

The Proof: A Case Study by the DOE. Even a test from 2004 with only 29% solar reflectivity (Evergreen) had a saving of $8,054 for Paulding County Georgia Elementary School, USA and showed even the supposed ‘winter penalty‘ was still minor in energy consumption to the cool roof summer advantages. Super Therm goes even further in energy savings.