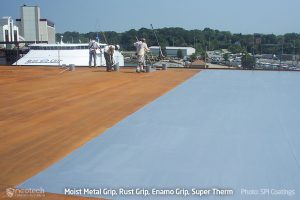

Marine

Marine coatings and corrosion control

What is the best way to protect wet rusted metal or steel that suffers from continues condensation or used underwater or underground?

Moist Metal Grip, our waterproof paint for metal, can be applied to dry or wet metal surfaces to protect against corrosion and chemicals in a two-part waterproof – water repelling epoxy coating. It was designed to be applied to surfaces that are not dry enough for other waterproof paints and coatings making it perfect for marine environments.

Moist Metal Grip is ideally suited for metal or steel surfaces that will be underwater or subjected to constant water pooling, condensation, high humidity, or steam. It can be applied directly over flash or surface rust without loss of adhesion.

It is resistant to chemicals and solvents, and is designed to be applied directly to metal, concrete, masonry, and wood. Moist Metal Grip is a perfect solution for protecting corroded, wet, or condensation cold water pipes. It can also be used to coat rebars for concrete, buried I-beams, water tanks, concrete floors, cooling towers, submerged structures, boats, and more.

You can easily apply it with a brush, roller, or sprayer and it can be used as a one-coating system. Moist Metal Grip can withstand temperatures up to 149°C/300°F.

Moist Metal Grip

Long lasting corrosion protection in wet or submersed environments

Moist Metal Grip is a tough adherent, 2 component Epoxy coatings, which produce hard, yet flexible coating films. These epoxy products will demonstrate excellent chemical and solvent resistance when utilised in harsh atmospheres, and will also provide outstanding water and humidity resistance.

These coatings will adhere tenaciously to a variety of substrates, such as carbon steel (phosphated or non-phosphated), wood and concrete. These products can be utilised in DTM (direct-to-metal) applications, with excellent success, as they have been fortified with a very efficient, non-toxic, rust inhibitive pigment > Learn More >

Rust Grip®

World’s toughest corrosion and encapsulation coating

Rust Grip® Is a one-part polyurethane coating that combines with atmospheric moisture to cure. Upon curing, Rust Grip® provides a protective coating of superior adhesion, flexibility and abrasion/impact-resistance. It is resistant to chemical solvents and acid splash.

Rust Grip® has passed over 15,000 hours of Salt Fog Test = 30 years (pdf).

Originally designed for metal surfaces, Rust Grip® demonstrates excellent adhesion to wood, concrete, fiberglass and many other substrates. Rust Grip® is designed for the encapsulation of and adherence to tightly-bonded surfaces of lead-based and other toxic paints as well as rusted surfaces > Learn More >

Enamo Grip

The ultimate protection coating

Enamo Grip is a tough, medium speed, moisture curing, two component polyurethane enamel, which will provide outstanding resistance to water and humidity, stains, chemicals, and solvents, as well as tremendous scuff, mar, and impact resistance. Ideal for use on bridges applied over Rust Grip® or by itself for complete encapsulation of the metal, providing protection from rust and corrosion for a minimum of 20 years in normal circumstances.

Resistant to hail damage and similar abuses that create opportunities for rust and corrosion. Completely UV-controlled and weather resistant. Enamo Grip can be used on flooring for a tough, long wearing surface. In summary, the overall toughness, durability, of Enamo Grip makes it the ideal choice for architectural maintenance situations that require the utmost in exterior durability. > Learn More >

Super Therm®

Super Therm® Ceramic Coating blocks 95% of solar heat

Super Therm® is used to coat over exterior surfaces in hot climates to block 95% of the solar heat (UV, Short Wave and Long Wave). Preventing Heat Load onto the initial surface or envelope of the building or structure reduces heat entering the interior.

The “Flame Spread Index” and “Smoke Spread Index” was “0” (out of 100). That is the highest classification available, a class “A” fire resistance rating. UL, Factory Mutual and NASA also performed fire rating and subsequent toxicity test on Super Therm®. Super Therm® rated excellent in absolutely no contribution to flame or fire. This is an unusual rating for any paint product as most will score from a low of 15 up to 88. The “A” classification is the highest classification that can be achieved. This result definitely shows the quality of Super Therm®. > Learn More >

Marine uses and benefits

The right coating for ultimate protection

- Floors

- Decks

- Walls & Ceilings

- Engine Rooms

- Work Boats

- Ferries

- Super Tankers

- Cruise Ships

- Casino Vessels

- Research Vessels

- Transport Vessels

- Other Modes of Water Transportation

Super Therm®

- Wheel houses

- Top decking to prevent heat buildup and conduction into holes

- Equipment and electronics on deck that need protection from heat

- Application of Super Therm® blocks sound by up to 68% through hulls, walls, etc.

- Application of Super Therm® resists the growth of mould and mildew

- Prevents the occurrence of condensation when applied to dry clean surfaces

- DNV approved

Rust Grip

- Prime entire hull – below and above water-line

- All metal on ship – interior and exterior

- Helps to prevent concrete from spaulding

- Can be applied with minimum prep and hand tooling

- Remove embedded salt deposits with wire brush or brush blast and a solvent wash

- Lay non-skid material down between two layers of the coating for an extremely durable footing – catwalks, decking, hallways, etc.

- DNV approved

Enamo Grip

- Top coat in colours for above water-line

- Can be used in white to top coat over Super Therm® to provide better weathering in ocean environment

- Used on interior for colour or clear

- Used on flooring in grey or clear with non-skid

Moist Metal Grip

- Apply over RUST GRIP on the exterior of the hull below the water line

- Coat directly over wet or moist pipes on interior to control condensation and corrosion

- Apply directly over wet surfaces – drys chemically

- Apply directly over interior of hull over wet or moist surfaces to prevent and encapsulate rust deposits

Omega Fire

- Apply on interior of engine rooms to prevent spread of fires

- Apply on interior of holes between compartment walls to prevent spread of fire

- Apply over all sensitive electrical and control boxes to protect from fire

- Apply on walls of sleep quarters and wheel houses

- Apply on interior walls of kitchen area and boiler rooms

- Tested for the U.S. Navy Carrier Group

- DNV approval pending

HPC (Hot Pipe Coating)

- Apply directly to surface of hot pipes and boilers during normal operation for insulation and protection

- Encapsulates hot surfaces to control corrosion

- Provides protective covering for hot surfaces and reduces exterior temperatures for a safer working environment

Lining Kote

- Apply inside of acid or caustic tanks or drip areas to prevent corrosion and deterioration