Super Therm® Testimonials

- Florida Energy Office

- Factory Heat Protection

- Home Solar Heat Block Protection

- Food Preparation areas

- Urethane Roofs

- Reducing fuel and saved produce in truck transportation

- Resurface Pool Decking and Heat Block

- Home Solar Heat Block Protection

- Condensation Management

- Shearing Shed Temperature Control

- Residential Home

- Utility Bills Reduction

- Interior Warehouse Heat Protection

- Aluminum Ducting Field Tests

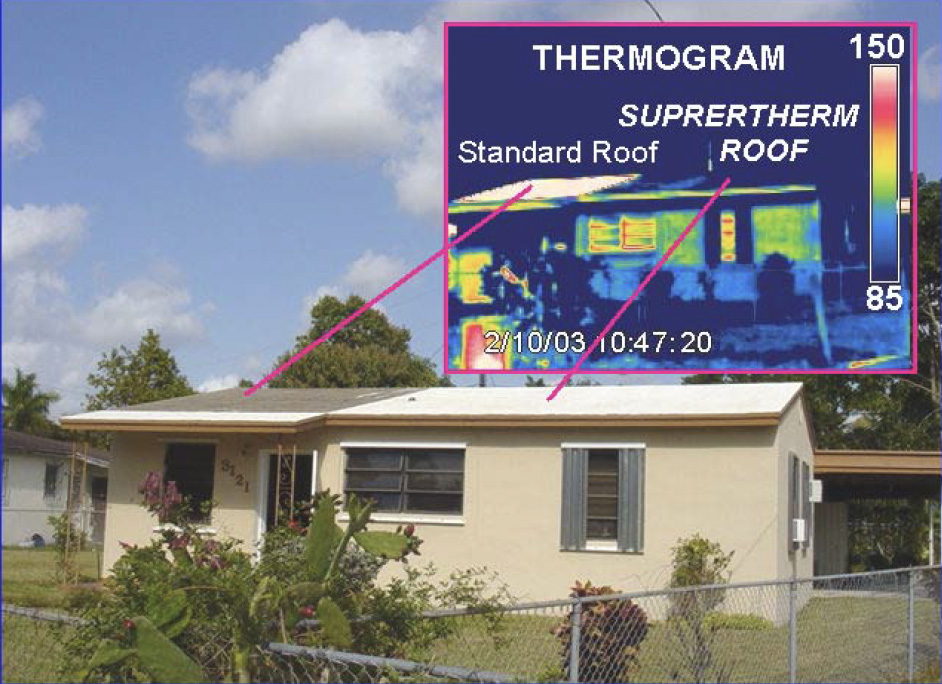

Florida Energy Office

As installed, at the time of this testing, the Super Therm® Roof Coating System proved to be an effective Energy Conservation Measure (ECM) that produced a reasonable simple pay back of approximately 2.2 years on this particular project. This would indicate that it’s application could be fundable with Federal and / or State of Florida Energy Grant Dollars where applicable.

On behalf of the The State of Florida Energy Office and the United States Environmental Protection Agency, let me thank you for your efforts in developing an affordable product that obviously can be instrumental in Conserving Energy. We hope you will continue to consider Florida as a valuable market for your products. See the full report PDF.

NOTE: Laboratory and Field project results as stated here may vary according to different climate conditions.

Factory Heat Protection

Thought you should know how Super Therm® performed for us at the Ag Enterprises manufacturing facility. It is very hard to cool various buildings at a factory because of size and volume most buildings have. We started cautiously by applying Super Therm® to the galvanized metal roof of one building to test its results.

We feel very pleased that our indoor working temperature went down an immediate 12° on our lower levels. Our attic storage and overhead work zones on the second story went down 24°. This has allowed us to use simple ceiling fans for our cooling in the summer. The metal surfaces went from 130° to 90°. We are stopping the heat at the source, not trying to exhaust an attic full of hot air. We have since found many other applications and hope to stay in touch with you on their results.

Roger Kuntz

Ag-Enterprises

Home Solar Heat Block Protection

About a year ago, a representative from the State Energy Commission visited one of our monthly meetings and advised us of your products. At that time, we were discussing ways of conserving energy in our neighborhood and seeking funds from his department for that purpose. We painted our first house with Super Therm® shortly thereafter and the results have been very satisfying.

The entire exterior of the house was coated with Super Therm®. After a year, the owner reported energy savings ranging between 10 and 20%. As a result of this success, we’ve decided to use Super Therm® exclusively in our Model Block Programs and are recommending your products to all homeowners in our other neighborhood projects, as well.

We’re painting an additional 9 houses with Super Therm® this year. We expect the results to be equally successful We’ll advise you of those results after a reasonable time period has elapsed. We are very happy with the job Super Therm® has done for us.

Walter Wright

President, Chesney Park NIA

Topeka, KS

Food Preparation areas

This product (Super Therm®) is chemically acceptable as a coating for application to structural surfaces or surfaces where there is a possibility of incidental food contact in official establishments operating under the Federal meat and poultry products inspection program. This letter does not authorize use of the coating on any surface where there is direct or prolonged contact with food. Before food product may be placed in the area where the material is being used, the area should be sufficiently free of odor to prevent product contamination.

As a safety precaution, smooth coatings should not be applied to walking or standing surfaces in processing areas. The final granting of authorization to use coatings on walls at ceilings, or on equipment surfaces below the product zone, is the responsibility of the inspector in charge of the official plant. Before applying the coating to equipment, which will subsequently be installed in an official plant, you must obtain clearance from the Equipment Standards and Review Branch, Meal and Poultry Inspection Technical Services in Washington, DC 20250. The Product Safety Branch upon request will provide technical advice. This letter acts as continuing authorization for as use under the conditions stated above.

Charles R Edwards, Chief

Product Safety Branch, Food Ingredient Assessment Division

United States Department of Agriculture

Urethane Roofs

This year we are going on our 4th year using Super Therm® as a topcoat for our urethane roofs and other types of roofs. Ceramics were a hard concept for me to accept, however, I know now this is a very effective coating and will do everything it is said to do. They do keep the heat and cold out. Super Therm® was not the first ceramic coating we experimented with. We had two other manufacturer’s products prior to finding Superior Products. The other ceramic coatings had major defects. One broke up and came off and the other one had to have a primer coat then a topcoat over the ceramic and I still did not like the company’s product.

Over smooth surfaces, we use only Super Therm®. If the surface is rough then we use Super Base as the base coat at the rate of 1.5 to 2 gallons per 100 square. This helps keep down the price and the Super Base is a very tough coating. We have not had any trouble with either product and in my opinion these are the best coatings on the market.

Jack Ayers

Rainbow Roofing Systems

Dodge City, KS

Reduced fuel and saved produce in truck transportation

During the latter part of 1989, I heard about a product called Super Therm® which was supposed to be able to reduce inside temperatures.

Being the owner of a fleet of primer movers pantech and tautliners I have continually had problems with heat buildup in the tautliners which are primarily used to cart bananas from Northern New South Wales to Adelaide. Temperatures are frequently around 35° up to 50°C. in mid-summer. This heat buildup causes the produce to rot and at times the loss rate could be as great as 15%. Bananas need to be carted at between 10°and 13°C but the tautliners with refrigeration units running constantly would run at a constant 19°C.

Although a little skeptical about any real benefits of Super Therm®, I decided to test the product with the following results:

- Inside the tautliner: when it is standing empty, it is noticeably cooler than a unit without Super Therm®.

- The motor on the refrigeration unit is set at 10°C. (normal temperature for carting bananas at that time) will in fact idle, hence a reduction in fuel costs to run the unit.

- The reduction in temperature due to Super Therm® has eliminated produce losses which of course was my prime concern, the added fuel saving being a bonus.

To anyone considering having Super Therm® applied to their pantech or tautliner, my comments could only be to delay the application is to waste money.

Bob Fountain Transport

Brisbane, Australia

Resurface Pool Decking and Heat Block

In 1989, we here at the Lawrence Travelodge had our pool deck resurfaced with Super Therm® coating. We had to do a lot of repair work on the deck due to the fact that there had been indoor outdoor carpeting on the deck. There was a lot of damage to the concrete beneath the carpet due to the freeze/thaw cycle in our part of the country. We have been very pleased with the way the product was able to adhere to the new concrete work.

We chose this product (Super Therm®) because of the claim that it would stay cool to the feet in the hot weather. We are very satisfied with the results. This product is also easy to maintain.

If I were to be asked what my most positive experience with this product was, I would have to say that it would be the cool comfort to bare feet. I never heard a complaint that the surface of the deck was too hot to walk on. The temperature in the summer gets up to 110°F and will stay there for days at a time. Our pool is for the enjoyment of our guests and there is not a day in the summer that the pool is not used to its fullest potential.

Bethany Willett, General Manager

Travelodge

Lawrence, KS

Home Solar Heat Block Protection

Well the good old Super Therm® has been put to the test with a vengeance over the past few days. The electronics on my air con have given up the ghost and since it is still under warranty, no one can fix it for a week.

So I can say that it has certainly been effective. On Saturday we had a top temperature of 37 degrees and by closing the windows and doors and pulling the curtains, the temperature inside was 29 degrees. Uncomfortable but not as uncomfortable as it could have been. Also the ceilings are quite cool which demonstrates the coating is doing its job.

Before that, when the air con was functioning, the unit ran for less time than it had in the past to maintain the desired temperature. As for costs, which is the real moment of truth, I have yet to run it for a full quarter with the insulation in place. The Energex bill arrived last week but since I did not take a reading of the usage from the date of installation, I have no comparisons. Next quarter should be more illuminating but with the weather so hot it is hard to establish any solid figures re operating. (Also Energex changed its method of billing during the quarter so it will require some fancy figuring to work it out.)

Overall the insulation is having a good effect. The patio area and the rumpus room which I seldom cool are markedly cooler now.

Ruth Jowett

to Graeme Byers, Australian Roofing Industries

Condensation Management

Your Super Therm® and SP40 Aqua were applied to the wood paneling of my cabin and effectively stopped condensation and, thereby, the rotting away of the wood. As I told you in person, the cabin also felt warmer after the application of Super Therm®. I suppose it is the result of the reflection of radiant heat.

John Nielsen

Chief Engineer

Seawind Fisheries

Shearing Shed Temperature Control

A shearing shed with the shearer working next to a corrugated iron wall in the afternoon sun. The shearer was working in temperatures of 50°C and complaining. I coated 100 square feet of the wall with Super Therm® and the iron temperature dropped 11°C. (52°F) instantly. Everyone wanted to know about the cost.

John Newbold

Hi-1h Coatings

Australia

Residential Home

My house is 61 years old. It was painted with one coat of Super Therm®. The complete house was painted with 2 brushes, a 3 inch and a 2 inch brush.

Super Therm® was tinted with 6 ounces of yellow to 5 gallons of Super Therm® to make a light ivory colour. Super Therm® was tinted with 2 ounces of medium green to 1 gallon to make the light green trimming. I used a total of 17 gallons of Super Therm®, 2 1/2 gallons of green and 14 gallons of ivory. Super Therm® was used as glue a couple of times on trim molding and screen frames where the use of nails or screws couldn’t do the repairs.

The house looks clean and very bright and the Super Therm® keeps the house cooler by 7 to 10 degrees. Hooray for Super Therm®! I am very pleased with the results.

Eugene Y.Q. Lung

Honolulu, HI

Utility Bills Reduction

About two years ago, we had a severe hailstorm and it literally tore my roof off. I had two estimates on it. The roofers were so busy, it was Christmas before they could get to it, but then I wouldn’t let them put my roof on in the cold weather. The roofers said I should call when I got ready. In the meantime, I heard about Super Therm® from Future Vision. The estimate I had on my damaged roof paid for the Super Therm®, so the insurance paid for the product.

My utility bills have been cut in just about half since I have had the Super Therm® on my roof. Last month, my utility bill was $87.00, and this time last year, it was $140.00. The Super Therm® was put on right over my old roof. It was rolled on with a paint roller. I am now in the process of painting my whole house with Super Therm®. When I went into the attic to put in an antenna, the attic was cooler than the house. Also, because my roof is so white from the Super Therm®, the Blue Angels used my house as a focal point when they were putting on the air show in Wichita.

Chris Clithero

Wichita, KS

Interior Warehouse Heat Protection

I just want to let you know how pleased we were with J.E.’s recommendation to coat the interior of the concrete wails and the 16 foot ceiling of our 1200 sq ft warehouse facility in Halawa Valley, Aica on Oahu, Hawaii.

It has now been almost 3 years, and the temperature in this warehouse/office/meeting facility to our reps is a steady 65 to 70 degrees, as is required for storing our nutritional supplements.

I am sure you will recall that the overhead garage entrance was replaced with a glass door and side windows. A local air conditioning company estimated that a 7 ton air conditioning unit would be required to cool the space. Instead, we purchased a 3 ½ ton unit, after spray painting the walls and the metal ceiling with Super Therm®.

The “system” is working well. Much of the time we are turning the air conditioning down or off, because it is getting so cool. The air conditioning people are amazed because their method of calculating BTUs needed to cool the area indicated a much bigger unit than the smaller one currently installed. They, too, are convinced the reason is the Super Therm® application.

Nancy Peevyhouse

Future Mart

Aluminium Ducting Field Tests

This is a brief summary of our field-testing results to date with the spray on heat block coating product Super Therm®. The product was applied July 15, 1996 by Wayru Contracting to aluminum dueling in an attempt to reduce the load on the machine room air conditioning unit by limiting the amount of heat gain through the duct wall. The surface temperature of the duct was 76°C \ 170°F.

The ducting was cleaned, primer applied and then approximately 760 microns \ 30 mils of the Super Therm® product applied. The surface temperature dropped from 76°C \ 170°F to approximately 32°C \ 90°F with the product adhering to the metal surface. In addition, the spray on product also helped seal the ductwork. To date, the reduction in temperature has been consistent with the initial test results and has successfully reduced the load on the air conditioning unit.

On August 6, 1996, Super Therm® was applied to a 150# steam line with a surface temperature of 173°C \ 345°F. Approximately 1400 microns \ 50 to 60 mils of the product were applied which reduced the surface temperature 40°C \ 105°F to 115°C \ 240°F. More testing took place on August 8, 1996, which involved applying 40-65 mils to the 150# steam line. This time the surface temperature was reduced from 208°C \ 408°F to 140°C \ 285-298° F. There was no discolouration of the product noted to date like that found with the Ceramic Cover product previously tested in May 1996.

In summary, I recommend the use of Super Therm® on aluminum ducting to reduce the surface heat of ductwork. Further applications of Super Therm® products will be identified in the future after thorough testing of the different products and only if positive test results are found.

Susan Dyer P Eng

Wayerhaeuser Canada

Kamloops Pull, Mill