THIS STUFF WORKS.

World’s Coating Innovator™

We help the planet solve big problems that Reduce Energy, Stop Corrosion, Give Personnel Protection and much more.

Recent News

NASA 2024 Spinoff Magazine for Super Therm - 35 years

Read More

Rust Grip® - Unequaled Corrosion Protection – Over 3,500,000 Feet of Completion Tubulars (Offshore Drill Pipe) with Zero Corrosion Downgrades

Read More

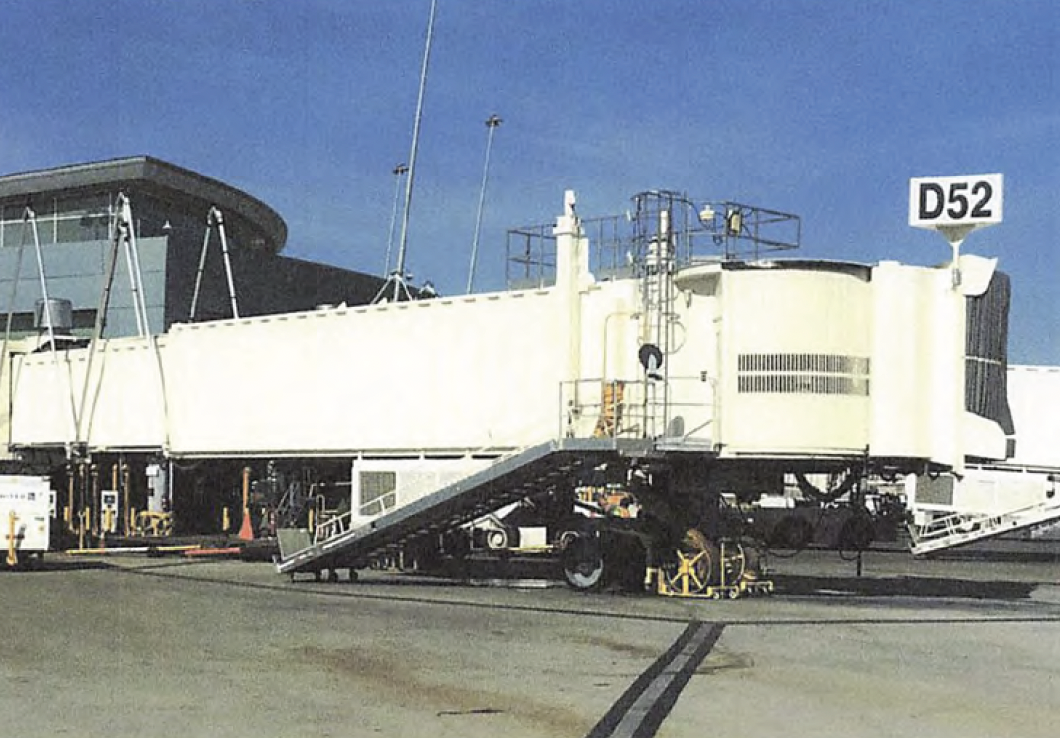

Super Therm® - Unequaled

Solar Radiation Heat

Reduction – 100 Passenger

Walkways Coated at

Harry Reid International

Airport in Las Vegas

SSPC Presentation

Insulative Coatings

Fit for Purpose

By: Arin Shahmoradian